Understanding the Benefits of High Pressure Plunger Pumps in Industrial Applications

Table of Contents

1. Introduction to High Pressure Plunger Pumps

2. How High Pressure Plunger Pumps Work

3. Key Advantages of High Pressure Plunger Pumps in Industrial Applications

3.1 Enhanced Efficiency and Performance

3.2 Versatility Across Different Industries

3.3 Reliability and Durability

4. Common Applications of High Pressure Plunger Pumps

4.1 Oil and Gas Industry

4.2 Water Treatment Facilities

4.3 Food and Beverage Processing

4.4 Chemical Manufacturing

5. Choosing the Right High Pressure Plunger Pump for Your Needs

5.1 Factors to Consider

5.2 Maintenance and Service Requirements

6. Frequently Asked Questions

7. Conclusion

1. Introduction to High Pressure Plunger Pumps

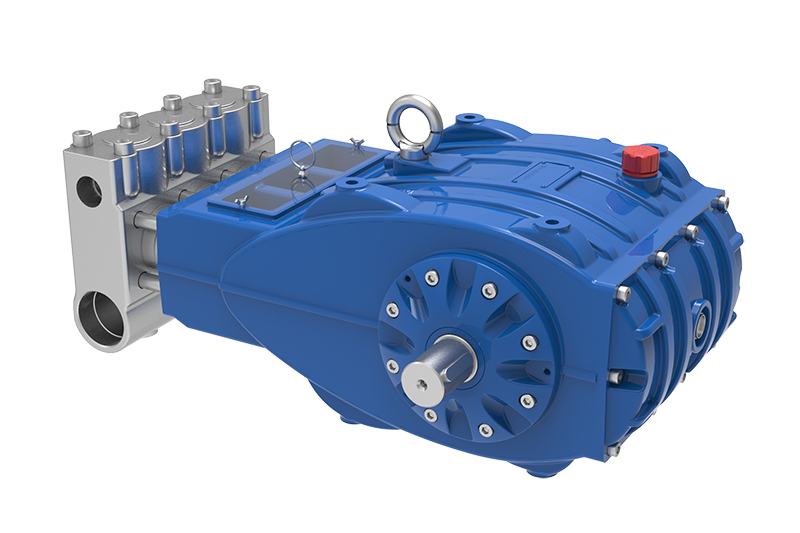

High pressure plunger pumps are essential components in various industrial applications, providing the reliability and performance needed for demanding tasks. These pumps are designed to handle high pressure and deliver fluids efficiently, making them ideal for applications that require precision and power. Whether used in oil and gas extraction or chemical processing, understanding the benefits of high pressure plunger pumps can significantly enhance operational effectiveness.

2. How High Pressure Plunger Pumps Work

At their core, high pressure plunger pumps operate on a simple principle: converting mechanical energy into hydraulic energy. The pump utilizes a plunger mechanism to create a vacuum that pulls fluid into the cylinder. As the plunger moves, it compresses the fluid and forces it out through an outlet. This process allows for the delivery of high flow rates under high pressure, which is crucial for many industrial processes.

The construction of these pumps typically includes durable materials, such as stainless steel, to withstand the harsh environments they often operate in. Their design ensures minimal wear and tear, which is critical for maintaining efficiency over time.

3. Key Advantages of High Pressure Plunger Pumps in Industrial Applications

3.1 Enhanced Efficiency and Performance

One of the primary benefits of high pressure plunger pumps is their exceptional efficiency. These pumps can handle large volumes of fluids at high pressures without compromising performance. Their design minimizes energy loss, which translates into lower operational costs and reduced energy consumption over time.

Additionally, high pressure plunger pumps deliver consistent performance across various flow rates, making them ideal for applications that require flexibility.

3.2 Versatility Across Different Industries

High pressure plunger pumps are used across a wide range of industries, thanks to their adaptability. From oil and gas to food processing, these pumps can be configured to meet the specific needs of each application. Their ability to handle different fluids, including viscous materials, further enhances their versatility, making them a preferred choice for many industrial operations.

3.3 Reliability and Durability

When it comes to industrial applications, reliability is paramount. High pressure plunger pumps are engineered for durability, capable of operating in extreme conditions and under significant stress. Their robust construction and advanced materials ensure they can withstand the rigors of daily use, reducing downtime and maintenance costs.

4. Common Applications of High Pressure Plunger Pumps

High pressure plunger pumps find utility in various sectors. Understanding their applications can help industries leverage their benefits effectively.

4.1 Oil and Gas Industry

In the oil and gas sector, high pressure plunger pumps are crucial for enhancing extraction processes. They are used to inject fluids into wells, facilitate the movement of crude oil, and even assist in water flooding operations. Their ability to handle high pressures ensures optimal performance in these demanding environments.

4.2 Water Treatment Facilities

Water treatment facilities rely heavily on high pressure plunger pumps for processes such as reverse osmosis. These pumps help in the filtration and purification of water, ensuring that it meets safety and quality standards. Their efficiency in moving large volumes of water quickly is vital in maintaining operational flow.

4.3 Food and Beverage Processing

In the food and beverage industry, high pressure plunger pumps are instrumental in various processes, such as pasteurization and sterilization. They ensure the consistent flow of materials, maintaining the quality and integrity of the products being processed.

4.4 Chemical Manufacturing

Chemical manufacturing also benefits from high pressure plunger pumps, which are used to transport and manage hazardous materials. Their ability to handle corrosive substances without degradation makes them indispensable in this sector.

5. Choosing the Right High Pressure Plunger Pump for Your Needs

Selecting the appropriate high pressure plunger pump for your specific application is crucial for optimizing performance.

5.1 Factors to Consider

When choosing a high pressure plunger pump, consider factors such as the fluid type, the required flow rate, and the operating pressure. Additionally, assess the material compatibility and any specific requirements your application may have to ensure optimal functionality.

5.2 Maintenance and Service Requirements

Regular maintenance is essential for ensuring the longevity and efficiency of high pressure plunger pumps. Consider the ease of serviceability when selecting a pump. Choose models that offer accessible components for routine checks and replacements.

6. Frequently Asked Questions

What is the typical lifespan of a high pressure plunger pump?

The lifespan of a high pressure plunger pump can vary based on usage and maintenance. However, with proper care, these pumps can last for many years, often exceeding a decade.

Can high pressure plunger pumps handle corrosive fluids?

Yes, many high pressure plunger pumps are designed with materials that resist corrosion, making them suitable for handling hazardous or corrosive fluids. Always check the manufacturer's specifications for compatibility.

How does the efficiency of high pressure plunger pumps compare to other pump types?

High pressure plunger pumps generally offer superior efficiency when handling high pressure and variable flow rates compared to other pump types, such as centrifugal pumps.

What maintenance is required for high pressure plunger pumps?

Routine maintenance may include checking seals and gaskets, monitoring fluid levels, and inspecting for wear and tear. Regular servicing helps prevent breakdowns.

Are high pressure plunger pumps suitable for low viscosity fluids?

While high pressure plunger pumps excel in handling viscous fluids, they can also manage low viscosity fluids effectively. However, their design is optimized for high pressure applications, so ensure the pump is suitable for your specific needs.

7. Conclusion

In conclusion, high pressure plunger pumps offer a myriad of benefits that make them essential in various industrial applications. Their efficiency, versatility, and durability ensure they meet the demands of modern manufacturing processes. Understanding the advantages of these pumps can help industries improve their operational effectiveness and reduce costs. By selecting the right high pressure plunger pump tailored to specific needs, companies can ensure optimal performance and reliability in their operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design