Understanding the Benefits of High Pressure Low Flow Pumps in Industrial Applications

Introduction to High Pressure Low Flow Pumps

High pressure low flow pumps play a crucial role in various industrial applications. These pumps are designed to deliver high pressure while maintaining a low flow rate, making them ideal for tasks that require precision and efficiency. Industries such as oil and gas, pharmaceuticals, and food processing rely on these pumps for their unique capabilities. In this article, we will explore the numerous benefits of high pressure low flow pumps and their significance in industrial processes.

What are High Pressure Low Flow Pumps?

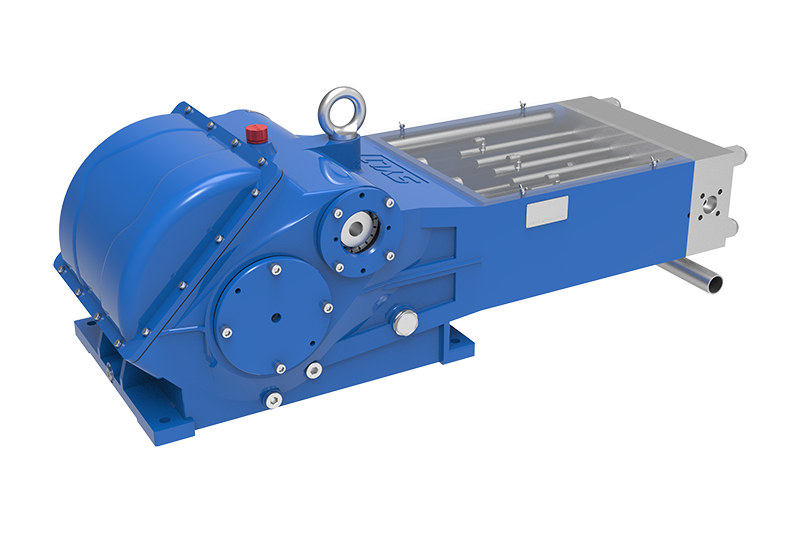

High pressure low flow pumps are specialized pumps engineered to achieve high discharge pressures with minimal fluid flow. They are often utilized in applications where the need for pressure outweighs the need for volume. The construction of these pumps includes robust materials and advanced technologies, allowing them to operate effectively under demanding conditions.

Types of High Pressure Low Flow Pumps

There are several types of high pressure low flow pumps, each suited for specific applications:

1. Positive Displacement Pumps

These pumps work by trapping a fixed volume of fluid and forcing it into the discharge pipe. Positive displacement pumps are ideal for applications requiring consistent flow rates and high pressures.

2. Centrifugal Pumps

While typically associated with higher flow rates, certain centrifugal pump designs can achieve high pressures when configured correctly. They are often used in chemical processing and water treatment applications.

3. Diaphragm Pumps

Diaphragm pumps are commonly employed in industries where contamination is a concern. They provide excellent sealing properties, ensuring that the fluid being pumped remains uncontaminated.

4. Piston Pumps

Piston pumps are known for their ability to produce high pressures with low flow rates, making them suitable for hydraulic applications and precise fluid dispensing.

Key Benefits of High Pressure Low Flow Pumps

High pressure low flow pumps offer numerous advantages that enhance industrial operations. Here, we will discuss the primary benefits these pumps provide.

1. Enhanced Efficiency

One of the standout benefits of high pressure low flow pumps is their ability to operate efficiently in applications where high pressure is essential. By minimizing the flow rate, these pumps reduce energy consumption, leading to lower operational costs.

2. Precision Control

High pressure low flow pumps allow for precise control over fluid delivery, making them ideal for applications that require accurate dosing and mixing. This precision is especially crucial in industries like pharmaceuticals, where exact measurements are vital.

3. Space-Saving Design

Due to their ability to generate high pressure with lower flow rates, high pressure low flow pumps can be more compact than traditional pumps. This compact design saves valuable floor space in industrial settings.

4. Versatility in Applications

These pumps are versatile and can be used across various industries and applications, from chemical processing to food and beverage production. Their adaptability makes them a valuable asset for many industrial operations.

5. Reduced Wear and Tear

High pressure low flow pumps are designed to handle demanding conditions, reducing wear and tear compared to standard pumps. This durability leads to decreased maintenance costs and longer service life, providing better return on investment.

6. Improved Safety

In many industrial environments, safety is a top priority. High pressure low flow pumps reduce the risk of leaks and spills by maintaining a sealed system, thus enhancing workplace safety.

Applications of High Pressure Low Flow Pumps

High pressure low flow pumps are utilized in various applications, each benefiting from their unique capabilities. Below are some of the most common uses in different industries.

1. Oil and Gas Industry

In the oil and gas sector, these pumps are used for enhanced oil recovery, hydraulic fracturing, and transferring viscous fluids. Their high-pressure capabilities ensure efficient operation under challenging conditions.

2. Pharmaceutical Manufacturing

Precision is crucial in pharmaceuticals. High pressure low flow pumps ensure accurate dosing of ingredients, leading to consistent product quality and compliance with stringent regulations.

3. Food and Beverage Processing

In food processing, maintaining hygiene is paramount. High pressure low flow pumps facilitate the transfer of liquids while minimizing contamination risks, making them ideal for this industry.

4. Chemical Processing

These pumps are often used in chemical processing for the safe transport of corrosive and hazardous materials. Their robust construction ensures reliability and safety in handling chemicals.

5. Water Treatment

In water treatment facilities, high pressure low flow pumps are essential for the effective filtration and distribution of water, ensuring that safety standards are met.

Choosing the Right High Pressure Low Flow Pump

Selecting the right pump for your application requires careful consideration. Here are some factors to evaluate when choosing a high pressure low flow pump.

1. Application Requirements

Identifying the specific needs of your application, including pressure and flow rate, is critical. Each pump type has its strengths, and understanding your requirements will guide you to the right choice.

2. Material Compatibility

Ensure that the pump materials are compatible with the fluids being handled. This consideration is crucial to prevent corrosion and maintain the integrity of the system.

3. Maintenance Needs

Evaluate the maintenance requirements of the pump. Some designs may require more frequent servicing than others, which can impact long-term operational costs.

4. Cost Considerations

While initial costs are important, consider the total cost of ownership, including maintenance, energy consumption, and potential downtime.

5. Manufacturer Reputation

Choose pumps from reputable manufacturers known for quality and reliability. Researching customer reviews and industry ratings can provide valuable insights.

Frequently Asked Questions (FAQs)

1. What are high pressure low flow pumps used for?

High pressure low flow pumps are used in various industries for applications requiring high pressure and accurate fluid delivery, such as oil and gas, pharmaceuticals, food processing, and chemical manufacturing.

2. How do high pressure low flow pumps work?

These pumps work by utilizing specific mechanisms, such as positive displacement or diaphragm actions, to generate high pressure while controlling flow rates.

3. What are the advantages of using high pressure low flow pumps over traditional pumps?

The advantages include enhanced efficiency, precision control, reduced wear and tear, and improved safety, making them ideal for demanding industrial applications.

4. Are high pressure low flow pumps expensive to maintain?

While the initial investment may be higher, their durability and efficiency often lead to lower maintenance costs and a better return on investment over time.

5. Can high pressure low flow pumps handle corrosive materials?

Yes, many high pressure low flow pumps are designed with materials that can withstand corrosive substances, making them suitable for chemical processing applications.

Conclusion

In summary, high pressure low flow pumps are indispensable in various industrial applications. Their ability to deliver high pressure with low flow rates, combined with their versatility, efficiency, and durability, makes them a preferred choice in many sectors. By understanding the benefits and applications of these pumps, industries can enhance their operational efficiency and ensure product quality. Investing in high pressure low flow pumps is not just a matter of choice but a strategic decision that can lead to significant advancements in industrial processes.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design