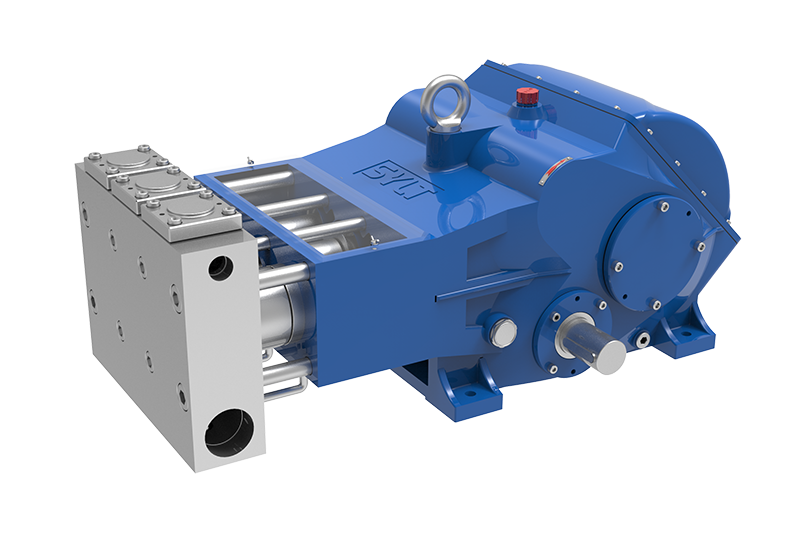

Industrial high pressure pumps are critical components in many industrial applications, designed to handle the demanding tasks of transporting fluids at elevated pressures. These pumps are engineered to provide reliable performance in challenging environments, making them indispensable in various sectors including manufacturing, oil and gas, chemical processing, and water treatment.

High-pressure pumps are capable of generating pressures far exceeding those of standard pumps, often reaching levels of several thousand psi. This capability allows them to efficiently transport liquids and slurries through long pipelines or to high elevations, where standard pumps may struggle. The design of high pressure pumps typically includes robust materials and advanced engineering to withstand the stress associated with high-pressure operation.

One of the key features of industrial high pressure pumps is their versatility. They can handle a wide range of fluids, including water, chemicals, and even abrasive materials. This adaptability makes them suitable for applications such as hydrostatic testing, hydraulic fracturing in the oil and gas industry, and the high-pressure cleaning of surfaces and equipment.

Another significant advantage of high pressure pumps is their efficiency in energy usage. When properly selected and maintained, these pumps can operate at high efficiencies, reducing operational costs and minimizing the environmental impact of their use. This is particularly important in today's industrial landscape, where sustainability and cost-effectiveness are paramount.

Maintenance is crucial for ensuring the longevity and reliability of industrial high pressure pumps. Regular inspection and timely replacement of worn components can prevent costly downtime and extend the life of the pump. It's also essential to ensure that the pump is correctly matched with the application requirements, including flow rate and pressure needs, to avoid unnecessary wear and tear.

Additionally, advancements in technology have led to the development of more sophisticated control systems for high pressure pumps. These systems allow for real-time monitoring of pump performance, enabling operators to optimize performance and detect issues before they lead to significant problems. Smart technology integration can also facilitate predictive maintenance, further enhancing the reliability of these pumps.

In conclusion, industrial high pressure pumps are vital for a wide array of applications across numerous industries. Their robust design, efficiency, and versatility make them an essential asset in any industrial setting. Understanding the features and maintenance needs of these pumps can help ensure optimal performance and reliability, thereby contributing to the overall success of industrial operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design