One of the primary applications of high pressure pumps is in the oil and gas industry, where they facilitate the extraction and transportation of crude oil and natural gas. These pumps assist in injecting fluids into the ground to enhance extraction efficiency and maintain reservoir pressure. Similarly, in the water treatment sector, high pressure pumps are used for reverse osmosis systems, where they pressurize water to separate contaminants, ensuring clean and safe drinking water.

Another significant application of high pressure pumps is in the manufacturing industry, particularly in processes such as surface cleaning and hydro blasting. High pressure water jets are utilized to remove rust, paint, and other debris from surfaces, which is critical for maintenance and preparation in industrial environments. The automotive and aerospace sectors also employ these pumps for precision cleaning of components before assembly.

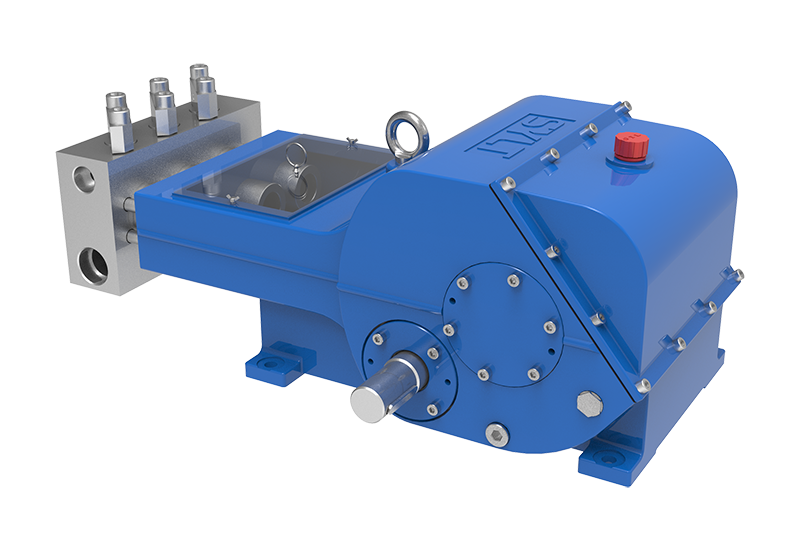

The benefits of high pressure pumps extend beyond their ability to move fluids efficiently. These pumps are engineered for durability and reliability, which are crucial in industrial settings that demand continuous operation. Additionally, high pressure pumps can be designed to operate with varying flow rates and pressures, allowing for flexibility in a wide range of applications. This adaptability means that businesses can optimize their processes, reduce downtime, and improve overall productivity.

Moreover, advancements in technology have led to the development of energy-efficient high pressure pumps. These modern designs not only help in reducing operational costs but also contribute to environmental sustainability by minimizing energy consumption and waste. Industries are increasingly recognizing the importance of selecting the right pump to meet their specific needs, which can lead to significant improvements in performance.

In conclusion, high pressure pumps play a vital role in various industrial applications, proving their worth in terms of efficiency, versatility, and reliability. Their ability to handle high pressures and flow rates makes them a critical asset in sectors such as oil and gas, water treatment, and manufacturing. By understanding the functionality and benefits of high pressure pumps, businesses can make informed decisions that enhance their operational capabilities and support sustainable practices in their processes.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design