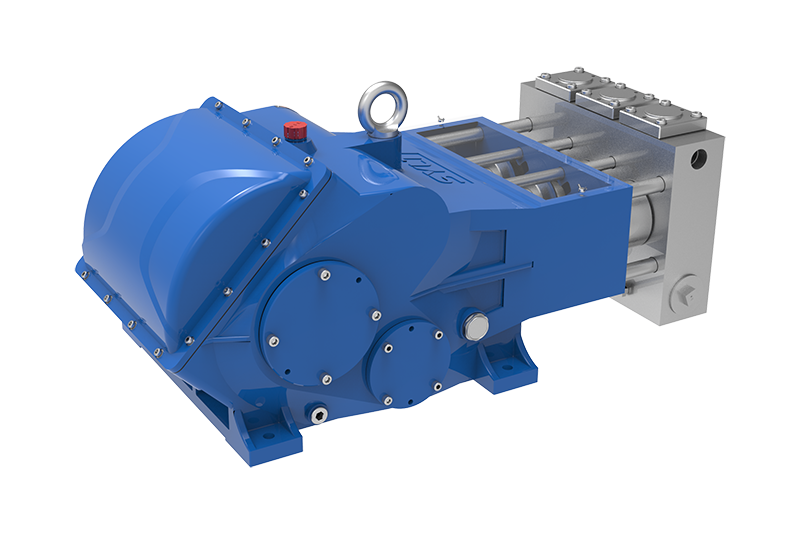

At the heart of a high pressure plunger pump is its plunger, which moves back and forth within a cylinder. As the plunger retracts, it creates a vacuum that draws the fluid into the chamber. When the plunger moves forward, it compresses the fluid, generating high pressure that forces the fluid out of the discharge port. This method of operation allows plunger pumps to handle various fluids, including corrosive, viscous, and abrasive materials, making them suitable for a wide range of industries such as oil and gas, chemicals, and food processing.

One of the main advantages of high pressure plunger pumps is their ability to generate high pressures, often exceeding 10,000 psi. This capability makes them ideal for applications such as pressure washing, hydraulic systems, and industrial cleaning, where effective fluid delivery is essential. Additionally, their robust construction and minimal maintenance requirements contribute to their longevity and reliability in demanding environments.

Moreover, high pressure plunger pumps are known for their efficiency. The positive displacement mechanism ensures that a consistent volume of fluid is delivered with each stroke, reducing the likelihood of pressure fluctuations. This feature is particularly beneficial in processes that require accurate dosing or mixing of fluids, ensuring that operations run smoothly and efficiently.

Another aspect to consider is the range of materials used in the construction of high pressure plunger pumps. Depending on the application, these pumps can be constructed with materials that resist corrosion and wear, enhancing their performance and lifespan. It is essential for industries to select pumps that are compatible with the specific fluids they will be handling, ensuring optimal functionality and safety.

In conclusion, high pressure plunger pumps play a vital role in modern industrial operations. Their ability to generate high pressures, coupled with their efficiency and reliability, makes them indispensable in various applications. For anyone involved in industries that require fluid handling, understanding the key features and benefits of high pressure plunger pumps is crucial to ensuring the success and efficiency of their operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design