One of the primary purposes of a high pressure booster pump is to elevate the pressure of water supply systems, ensuring thatwater is delivered effectively to different points of use, especially in multi-story buildings, irrigation systems, and industrial processes. By enhancing the pressure, these pumps facilitate the smooth operation of plumbing systems and various machinery that require specific pressure levels to function correctly.

High pressure booster pumps find extensive use in the manufacturing sector, where they play a pivotal role in processes that require precise fluid control. For example, in the food and beverage industry, these pumps ensure that liquids are transported at the right pressure for processing and packaging, which is crucial for maintaining product quality and safety. Similarly, in the chemical industry, high pressure booster pumps manage the transfer of reactive substances, where maintaining the right pressure is vital for safety and efficiency.

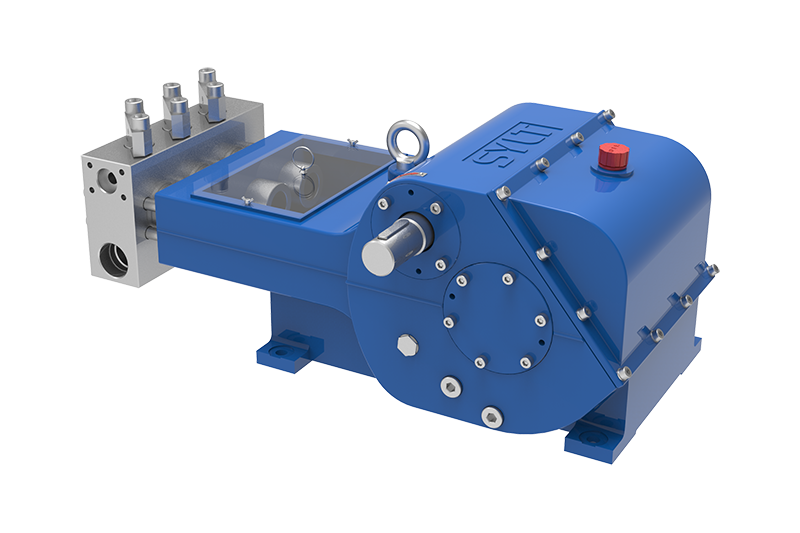

An essential feature of high pressure booster pumps is their ability to handle varying flow rates while maintaining consistent pressure. This adaptability is critical in applications where demand fluctuates, allowing for seamless integration into existing systems. Additionally, advanced designs often incorporate energy-efficient technologies, reducing operational costs and minimizing environmental impact.

Maintenance is another important aspect to consider when working with high pressure booster pumps. Regular checks and servicing can prevent costly downtime and extend the lifespan of the equipment. It’s crucial to monitor factors such as pressure levels, flow rates, and potential wear and tear on components to ensure optimal performance.

In conclusion, high pressure booster pumps are indispensable tools in industrial environments where pressure management is crucial. Understanding their functionalities and applications can help businesses enhance efficiency and productivity. By leveraging these pumps effectively, industries can meet their operational demands while ensuring safety and reliability. Investing in the right booster pump technology is an investment in the future of any industrial operation.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design