Analysis of Municipal High-Pressure Piston Pumps

Introduction

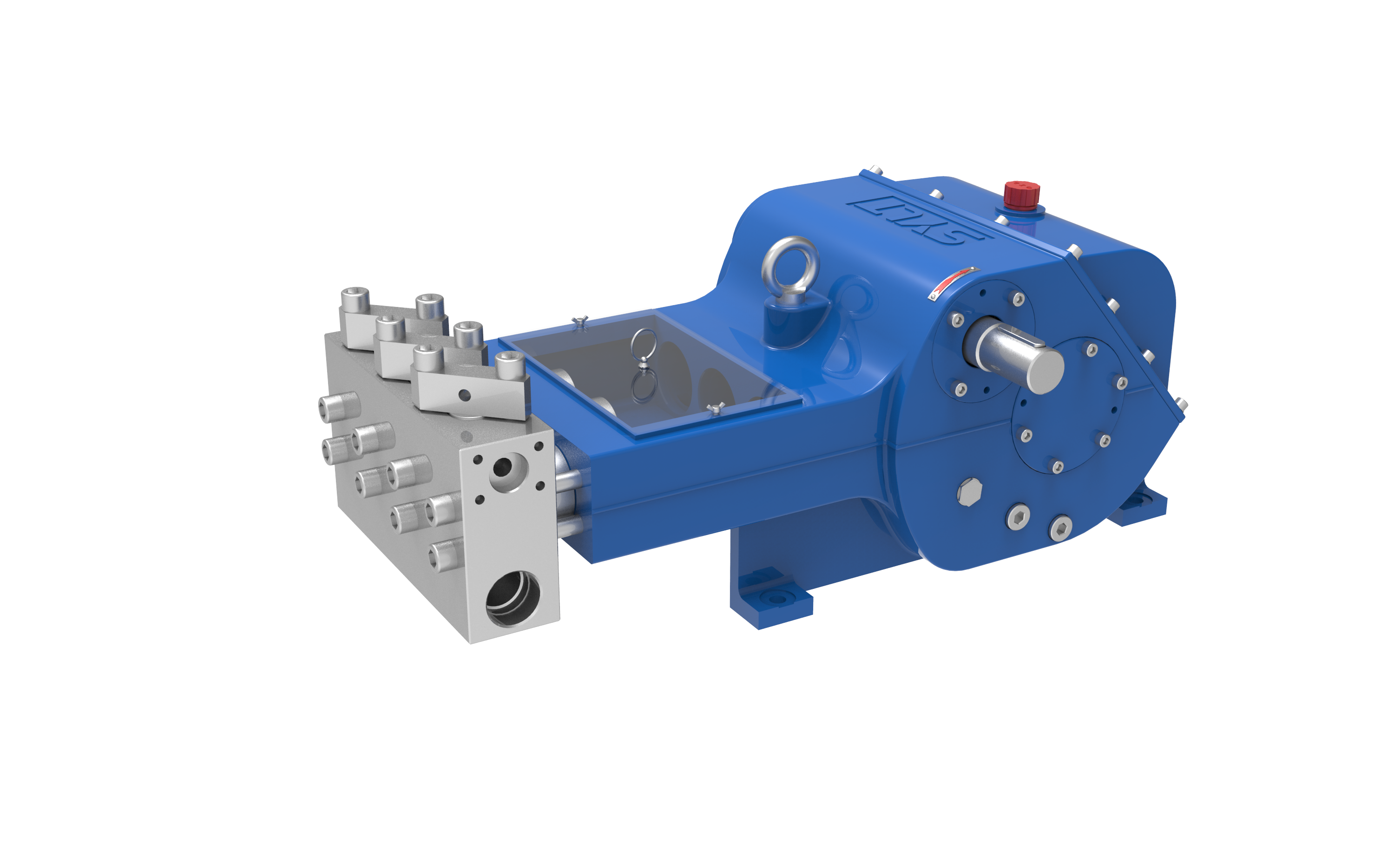

Municipal high-pressure piston pumps are one of the essential key devices in municipal engineering, widely used in water supply, drainage, fire protection, sewage treatment, and other fields. Their efficient, stable, and durable characteristics play an important role in municipal infrastructure. This article will provide a detailed analysis of municipal high-pressure piston pumps from aspects such as working principle, structural characteristics, application fields, advantages and disadvantages, maintenance, and future development trends.

I. Working Principle

Municipal high-pressure piston pumps are a type of volumetric pump, and their working principle is based on the reciprocating motion of the piston within the cylinder. When the piston moves backward, the volume in the pump chamber increases, creating a negative pressure, and liquid enters the pump chamber through the inlet valve; when the piston moves forward, the volume in the pump chamber decreases, the liquid is compressed, and is discharged through the outlet valve. Through this reciprocating motion, the piston pump can achieve the delivery of high-pressure liquids.

The working pressure of piston pumps is usually quite high, reaching tens or even hundreds of megapascals, so they are often used in municipal engineering for high-pressure water supply, fire protection systems, high-pressure cleaning, and other scenarios.

II. Structural Characteristics

The main structure of municipal high-pressure piston pumps includes the following parts:

1. Piston and Cylinder: The piston is the core component of the pump, usually made of high-strength alloy steel, with a hardened surface to improve wear resistance. The cylinder is the chamber for the piston movement, typically made of cast iron or stainless steel, with good sealing and corrosion resistance.

2. Inlet Valve and Outlet Valve: The inlet and outlet valves are key components that control the entry and exit of liquid in the pump chamber. The inlet valve opens when the piston moves backward, allowing liquid to enter the pump chamber; the outlet valve opens when the piston moves forward, allowing liquid to exit the pump chamber. The design of the valves directly affects the efficiency and reliability of the pump.

3. Drive Device: Piston pumps are usually driven by electric motors, diesel engines, or hydraulic systems. Electric motor-driven piston pumps are suitable for fixed locations, while diesel engine-driven piston pumps are suitable for mobile equipment or field operations.

4. Sealing Device: Due to the high working pressure of piston pumps, the design of the sealing device is crucial. Common sealing methods include packing seals and mechanical seals, ensuring that the pump maintains good sealing performance under high pressure.

5. Lubrication System: The lubrication system of the piston pump is used to reduce friction between the piston and the cylinder, extending the service life of the equipment. The lubrication method can be oil lubrication or water lubrication, depending on the working environment and medium of the pump.

III. Applications

Municipal high-pressure piston pumps are widely used in municipal engineering, mainly including the following aspects:

1. Water Supply System: In municipal water supply systems, high-pressure piston pumps are used to transport water from the water source to the water treatment plant or from the water treatment plant to the urban water supply network. Their high-pressure characteristics can overcome resistance in long-distance transportation, ensuring the stable operation of the water supply system.

2. Fire Protection System: High-pressure piston pumps are one of the core devices in fire protection systems, used to provide high-pressure water sources, ensuring that fire hydrants and sprinkler systems can quickly start and function in emergencies.

3. Sewage Treatment: In sewage treatment plants, high-pressure piston pumps are used to lift sewage from low to high places or for the transportation and treatment of sludge. Their corrosion resistance and high-pressure characteristics enable them to handle sewage containing solid particles.

4. High-Pressure Cleaning: In municipal engineering, high-pressure piston pumps are often used for road cleaning, pipeline cleaning, and building exterior wall cleaning. Their high-pressure water flow can effectively remove dirt and deposits, improving cleaning efficiency.

5. Drainage System: During heavy rain or flooding, high-pressure piston pumps are used to quickly remove accumulated water, preventing urban flooding. Their high flow and high-pressure characteristics make them perform excellently in emergency drainage operations.

IV. Advantages and Disadvantages

Advantages

1. High Pressure Output: Municipal high-pressure piston pumps can provide extremely high output pressure, suitable for situations requiring high-pressure liquids, such as fire protection systems and high-pressure cleaning.

2. High Efficiency and Stability: Piston pumps have high efficiency and can maintain stable output performance during long-term operation, suitable for continuous operations in municipal engineering.

3. Strong Durability: The key components of piston pumps are usually made of high-strength materials, with good wear and corrosion resistance, resulting in a long service life.

4. Strong Adaptability: Piston pumps can handle various media, including clean water, sewage, sludge, etc., with a wide range of applications.

Disadvantages

1. Complex Structure: The structure of piston pumps is relatively complex, with higher manufacturing costs and maintenance requirements.

2. High Noise: Due to the reciprocating motion of piston pumps, they generate significant noise during operation, especially under high-pressure conditions, where noise issues are more pronounced.

3. Vibration Issues: Piston pumps produce a certain amount of vibration during operation, especially under high-pressure conditions, which may affect the stability and service life of the equipment.

4. High Maintenance Costs: The sealing devices, pistons, and cylinders of piston pumps require regular maintenance and replacement, leading to high maintenance costs.

V. Maintenance

To ensure the long-term stable operation of municipal high-pressure piston pumps, regular maintenance is essential. The following are common maintenance measures:

1. Regularly Check Sealing Devices: The sealing device is a key component of the piston pump; regularly check the wear of sealing parts and promptly replace damaged seals to ensure the pump's sealing performance.

2. Lubrication System Maintenance: Regularly check the lubrication system to ensure sufficient and clean lubricating oil, reducing friction between the piston and the cylinder, and extending the service life of the equipment.

3. Check the valves: Regularly check the working status of the intake and discharge valves to ensure that the valves open and close flexibly, avoiding a decrease in pump efficiency due to valve failure.

4. Vibration and noise monitoring: Regularly monitor the vibration and noise of the pump, promptly detect and address abnormal vibrations and noises to prevent equipment damage.

5. Cleaning and maintenance: Regularly clean the interior and exterior of the pump, remove dirt and deposits, keep the pump clean, and prevent corrosion and blockage.

VI. Future Development Trends

With the continuous development of municipal engineering and technological advancements, municipal high-pressure plunger pumps are also continuously improving and upgrading. The future development trends are mainly reflected in the following aspects:

1. Intelligence: With the development of the Internet of Things and artificial intelligence technologies, future municipal high-pressure plunger pumps will become more intelligent. Through sensors and control systems, the operating status of the pump will be monitored in real-time, automatically adjusting working parameters to improve operational efficiency and reliability.

2. Energy saving and environmental protection: Future plunger pumps will pay more attention to energy saving and environmental protection, using efficient motors and energy-saving technologies to reduce energy consumption and carbon emissions. At the same time, the materials and designs of the pumps will be more environmentally friendly, reducing their impact on the environment.

3. Modular design: Future plunger pumps will adopt modular designs, making installation, maintenance, and upgrades easier. Users can choose different modules based on actual needs, enhancing the flexibility and adaptability of the equipment.

4. Application of new materials: With the development of new material technologies, future plunger pumps will use more wear-resistant and corrosion-resistant materials, extending the service life of the equipment and reducing maintenance costs.

5. Multifunctional integration: Future plunger pumps will integrate more functions, such as automatic cleaning, automatic lubrication, and automatic alarms, improving the automation level and operational convenience of the equipment.

Conclusion

As an important piece of equipment in municipal engineering, municipal high-pressure plunger pumps play a significant role in water supply, drainage, fire protection, and sewage treatment due to their efficient, stable, and durable characteristics. Despite some shortcomings such as complex structure and high noise levels, the performance and reliability of plunger pumps will be further enhanced through continuous technological improvements and maintenance. In the future, with the development of technologies such as intelligence and energy saving and environmental protection, municipal high-pressure plunger pumps will usher in a broader application prospect.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design