The five-plunger high-pressure pump and the three-plunger high-pressure pump are two common types of high-pressure pumps, widely used in industries such as agriculture, construction, and more. They have significant differences in structure, performance, and application scenarios. Below is a detailed comparative analysis of these two types of high-pressure pumps.

1. Structural Differences

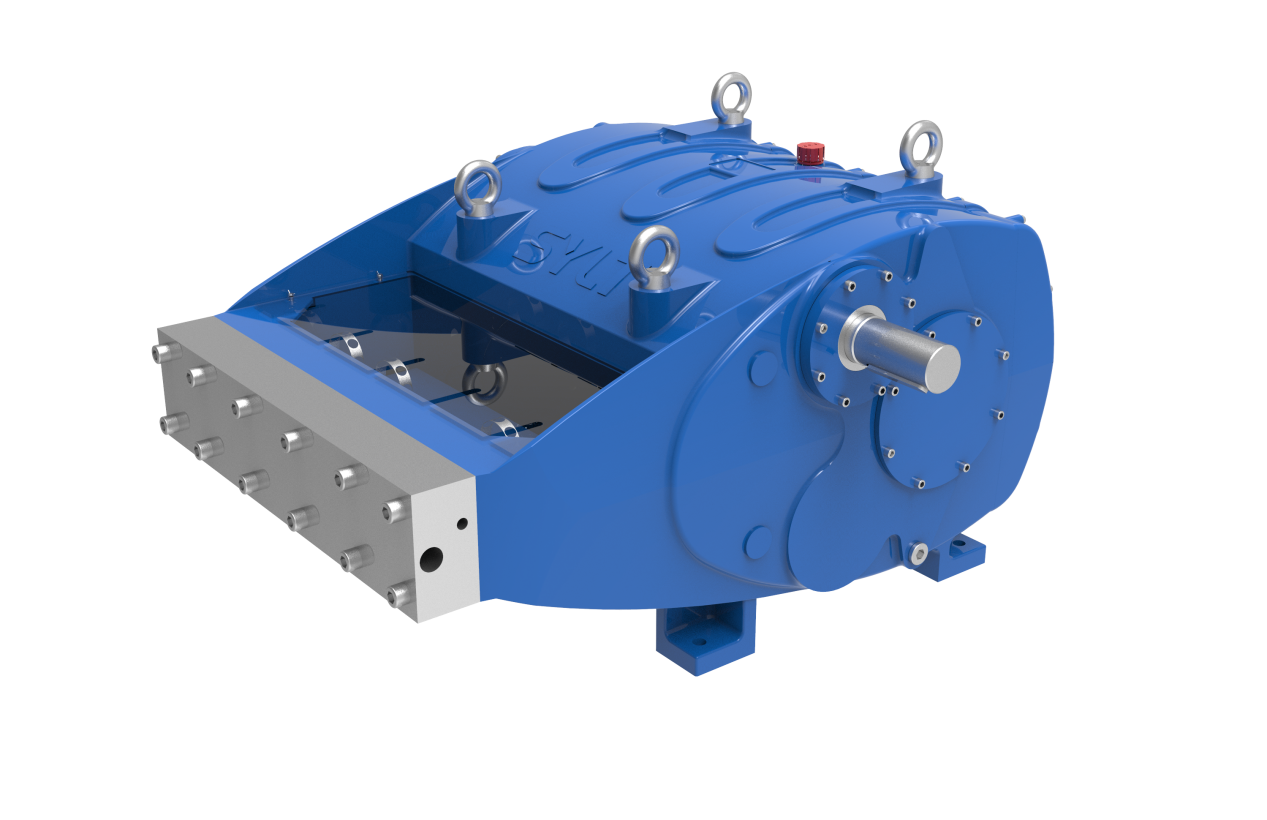

- Five-plunger high-pressure pump: As the name suggests, the five-plunger high-pressure pump has five plungers, usually arranged in a star shape. This design allows for a smoother flow output and smaller pressure fluctuations. The structure of the five plungers is relatively complex, with higher manufacturing costs, but due to the larger number of plungers, the load on each plunger is smaller, resulting in a longer overall lifespan.

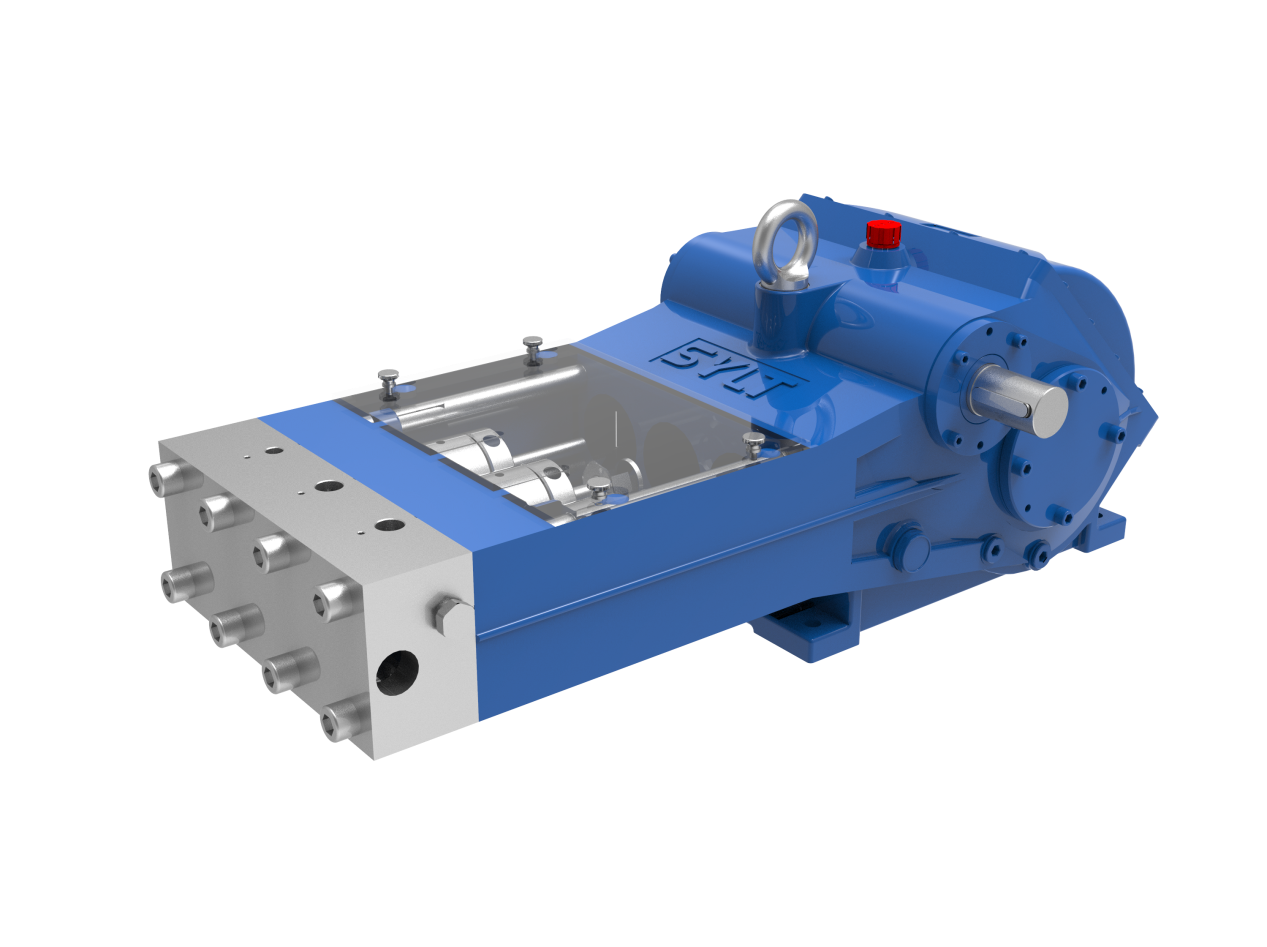

- Three-plunger high-pressure pump: The three-plunger high-pressure pump has three plungers, usually arranged at 120-degree angles. The structure is relatively simple, with lower manufacturing costs. However, due to the fewer number of plungers, the load on each plunger is larger, which can lead to increased wear and a relatively shorter lifespan. Additionally, the flow output of the three-plunger pump fluctuates more, and its pressure stability is poorer.

2. Performance Comparison

- Flow and Pressure Stability: The five-plunger high-pressure pump has a larger number of plungers, resulting in smoother flow output and smaller pressure fluctuations, making it suitable for situations with high pressure stability requirements. In contrast, the three-plunger high-pressure pump has larger flow output fluctuations and poorer pressure stability, making it suitable for situations with lower pressure stability requirements.

- Efficiency and Energy Consumption: The efficiency of the five-plunger high-pressure pump is generally higher, with lower energy consumption. Due to the larger number of plungers, the load on each plunger is smaller, allowing for smoother overall operation and relatively lower energy consumption. The three-plunger high-pressure pump, on the other hand, has fewer plungers, resulting in a larger load on each plunger, lower efficiency, and higher energy consumption.

- Noise and Vibration: The five-plunger high-pressure pump, due to its complex structure, operates smoothly with less noise and vibration. In contrast, the three-plunger high-pressure pump, with its simpler structure, does not operate as smoothly, resulting in more noise and vibration.

3. Application Scenarios

- Five-plunger high-pressure pump: Due to its high flow and pressure stability, it is suitable for situations with high pressure stability requirements, such as precision cleaning, high-pressure water jet cutting, and high-pressure transportation in the chemical industry. Additionally, the five-plunger high-pressure pump is widely used in applications requiring long continuous operation, such as oil extraction and mine drainage.

- Three-plunger high-pressure pump: Due to its simple structure and low cost, it is suitable for situations with lower pressure stability requirements, such as agricultural irrigation and high-pressure cleaning at construction sites. Furthermore, the three-plunger high-pressure pump is widely used in cost-sensitive applications with lower performance requirements.

4. Maintenance and Lifespan

- Five-plunger high-pressure pump: Due to the larger number of plungers, the load on each plunger is smaller, resulting in a longer overall lifespan. However, due to its complex structure, maintenance costs are higher, requiring regular inspection and replacement of plungers, seals, and other wear parts.

- Three-plunger high-pressure pump: Due to the fewer number of plungers, the load on each plunger is larger, resulting in a shorter overall lifespan. However, due to its simple structure, maintenance costs are lower, but the frequency of replacing wear parts is higher.

5. Cost Comparison

- Five-plunger high-pressure pump: Due to its complex structure, manufacturing costs are higher, but it has high operational efficiency and low energy consumption, resulting in lower long-term usage costs. It is suitable for users with high performance requirements and sufficient budgets.

- Three-plunger high-pressure pump: Due to its simple structure, manufacturing costs are lower, but it has low operational efficiency and high energy consumption, resulting in higher long-term usage costs. It is suitable for users who are cost-sensitive and have lower performance requirements.

6. Summary

- Five-plunger high-pressure pump: Suitable for situations with high requirements for pressure stability, efficiency, and lifespan, but with higher initial investment and maintenance costs.

- Three-plunger high-pressure pump: Suitable for cost-sensitive situations with lower performance requirements, but with higher long-term usage costs and maintenance frequency.

When selecting a high-pressure pump, users should consider the specific application needs, budget, and usage environment, taking into account the above factors to choose the most suitable type of high-pressure pump.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design