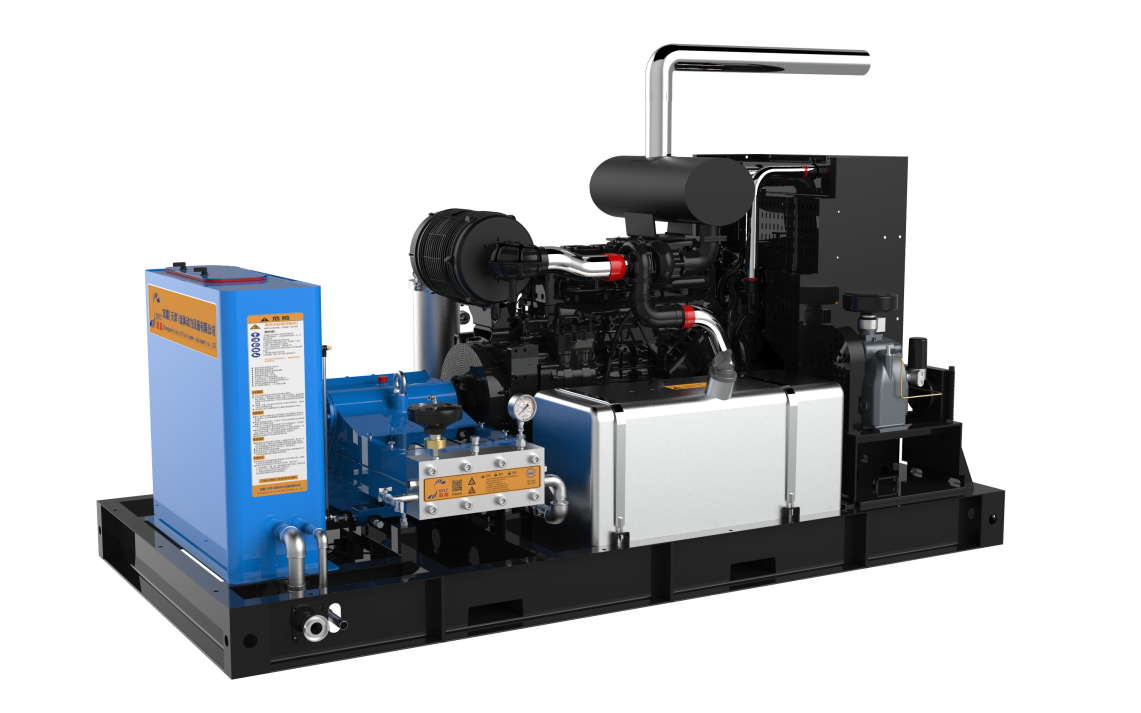

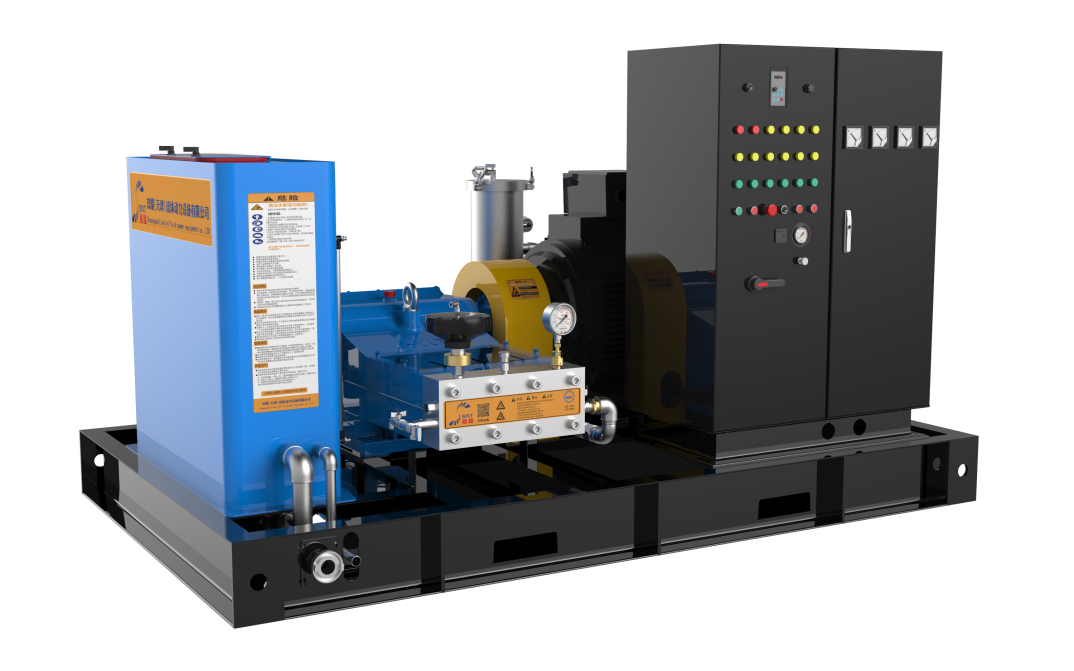

Application scenarios and operating conditions of 2800bar high-pressure plunger pumps

The 2800bar high-pressure plunger pump has a wide range of applications in multiple fields due to its ultra-high output pressure, especially in scenarios that require extremely high pressure. The following are its main application scenarios and operating conditions:

I. Application Scenarios

1. Water jet cutting:

The 2800bar high-pressure plunger pump is the core power source of water jet cutting equipment, capable of generating ultra-high pressure water jets for cutting hard materials such as metals, stones, glass, and composite materials.

Advantages: High cutting precision, narrow cutting seam, small heat-affected zone, environmentally friendly and pollution-free.

2. High-pressure cleaning:

Used for cleaning stubborn dirt, oil stains, rust, etc., on the surfaces of industrial equipment, pipelines, ships, and vehicles.

Advantages: High cleaning efficiency, good cleaning effect, saves water resources, reduces the use of chemical cleaning agents.

3. Petrochemical:

Used for water injection in oil fields, pipeline pressure testing, and sealing tests of wellhead devices.

Advantages: High pressure, large flow, high reliability, able to meet the strict requirements of the petrochemical industry for high-pressure equipment.

4. Scientific research:

Used for ultra-high pressure experimental research in fields such as materials science, geophysics, and biomedicine.

Advantages: Stable pressure, high control precision, able to provide a reliable ultra-high pressure environment for scientific research.

II. Operating Conditions

1. Working pressure: 2800bar, belonging to the ultra-high pressure range.

2. Working medium: Usually water, emulsion, or oil.

3. Working temperature: The working temperature range varies according to specific application scenarios, generally between -20℃ and 80℃.

4. Working environment: May exist in harsh environments such as vibration, impact, dust, and humidity.

5. Maintenance: Regular replacement of seals, filter elements, and other consumables is required, along with lubrication maintenance.

III. Selection Recommendations

When selecting a 2800bar high-pressure plunger pump, the following factors need to be considered:

Flow: Choose an appropriate flow rate based on actual needs.

Pressure: Ensure the pump's rated pressure meets the usage requirements.

Medium: Select pump materials and seals compatible with the working medium.

Working environment: Choose the appropriate protection level and cooling method suitable for the working environment.

Brand and service: Choose well-known brands and suppliers that provide comprehensive After-sale Service.

IV. Development Trends

With the advancement of technology, the 2800bar high-pressure plunger pump will develop in the following directions:

Higher pressure: To meet more demanding application needs.

Higher efficiency: To reduce energy consumption and improve economic benefits.

More intelligent: To achieve remote monitoring, fault diagnosis, and other functions.

More environmentally friendly: To reduce noise and leakage, minimizing environmental impact.

In summary, the 2800bar high-pressure plunger pump, as an important high-pressure power device, plays a significant role in multiple fields. With the continuous development of technology, its application range will become even broader, and its performance will be even better.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design