Why the CE Water Jet Cleaning Machine is Essential for Industrial Cleaning

Introduction to Water Jet Cleaning Technology

In the ever-evolving world of industrial cleaning, efficiency and effectiveness are paramount. One revolutionary tool that has transformed the landscape of industrial cleaning is the **CE Water Jet Cleaning Machine**. This advanced cleaning technology utilizes high-pressure water jets to eliminate tough contaminants, ensuring surfaces remain spotless and safe.

The Mechanics of Water Jet Cleaning

Understanding how the CE Water Jet Cleaning Machine operates is crucial for appreciating its benefits.

How Water Jet Cleaning Works

At its core, the machine generates a high-pressure stream of water that can reach speeds of over 1,500 psi. This powerful jet dislodges dirt, grime, grease, and other stubborn substances from various surfaces. The combination of pressure and the focused nature of the water jet allows for thorough cleaning without the need for harsh chemicals.

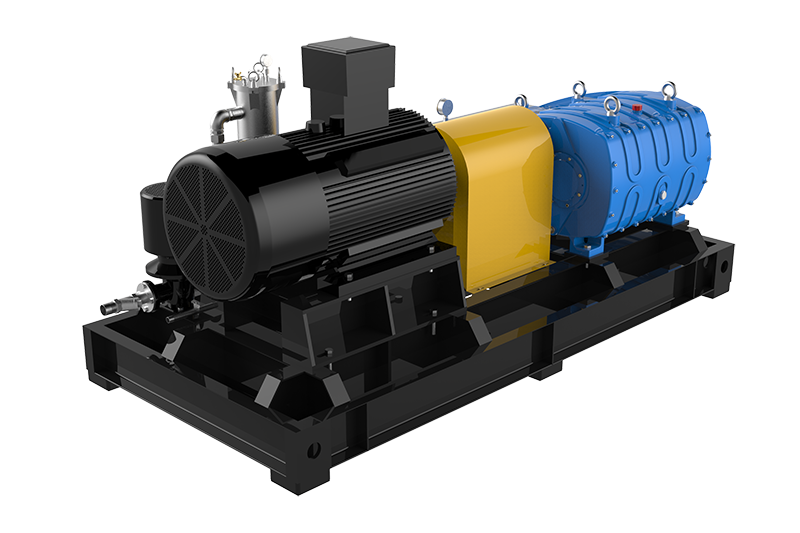

Key Components of the CE Water Jet Cleaning Machine

1. **Pump**: The heart of the machine, generating the necessary pressure.

2. **Nozzle**: Designed to control the direction and intensity of the water jet.

3. **Hoses**: High-pressure hoses that withstand the intense forces generated by the machine.

4. **Controls**: User-friendly interfaces that allow operators to adjust settings based on specific cleaning tasks.

Advantages of Using the CE Water Jet Cleaning Machine

The CE Water Jet Cleaning Machine offers a multitude of benefits that contribute to its essential status in industrial cleaning.

1. Environmentally Friendly Cleaning

One of the significant advantages of water jet cleaning is its environmental impact. Traditional cleaning methods often rely on harmful chemicals, which can be detrimental to both health and the environment. The CE Water Jet Cleaning Machine, however, primarily uses water, making it a safer alternative.

2. Cost-Effectiveness

While the initial investment in a CE Water Jet Cleaning Machine may seem substantial, the long-term savings are significant. Reduced need for chemicals, less water wastage, and decreased labor costs contribute to a favorable return on investment.

3. Versatility Across Industries

The CE Water Jet Cleaning Machine is not limited to a single industry. Its versatility allows it to be employed in various sectors, including automotive, manufacturing, and food processing. Whether cleaning equipment, machinery, or surfaces, this machine adapts to meet diverse cleaning needs.

Common Applications of Water Jet Cleaning

- **Industrial Equipment Cleaning**: Effectively removes oil and grease from machinery.

- **Surface Preparation**: Prepares surfaces for painting or coating by removing contaminants.

- **Pipe Cleaning**: Cleans and unblocks pipes with precision.

Why CE Certification Matters

When investing in cleaning equipment, it’s essential to consider safety and compliance. **CE certification** signifies that the Water Jet Cleaning Machine meets European safety standards, ensuring reliability and quality. This certification provides peace of mind, confirming that the equipment is safe for use in industrial settings.

Comparative Analysis: Water Jet Cleaning vs. Traditional Methods

In order to understand the advantages of the CE Water Jet Cleaning Machine, it’s essential to compare it against traditional cleaning methods.

Effectiveness

Traditional methods, such as scrubbing and chemical cleaning, may require extensive manual effort and time. In contrast, the water jet cleaning method offers a faster and more thorough clean, often requiring less labor.

Safety

Chemical cleaning methods pose risks such as chemical burns and harmful fumes. The water jet cleaning method minimizes these risks, offering a safer alternative for workers.

Cost Analysis

While traditional cleaning might appear cheaper upfront, the cumulative costs of labor, chemicals, and disposal can accumulate significantly. The CE Water Jet Cleaning Machine, despite its higher initial cost, tends to offer substantial savings in the long run.

Best Practices for Operating a CE Water Jet Cleaning Machine

To maximize the effectiveness and longevity of your water jet cleaning machine, following best practices is crucial.

1. Proper Training

Operators should receive comprehensive training to understand the machine's functions and safety protocols. This reduces the risk of accidents and ensures effective cleaning.

2. Regular Maintenance

Routine maintenance checks can prolong the lifespan of the machine. This includes inspecting hoses, nozzles, and connections for wear and tear.

3. Adhering to Safety Protocols

Using personal protective equipment (PPE) such as goggles and gloves is essential to safeguard operators during cleaning tasks.

Real-World Case Studies

Several industries have reaped significant benefits from implementing the CE Water Jet Cleaning Machine.

Case Study 1: Automotive Industry

A leading automotive manufacturer integrated the CE Water Jet Cleaning Machine in their assembly line. They reported a 30% reduction in cleaning time and a 25% decrease in chemical usage, contributing to a cleaner and safer work environment.

Case Study 2: Food Processing

In a food processing facility, the water jet cleaning machine effectively eliminated biofilm and grease buildup in processing equipment. This enhanced food safety, reduced equipment downtime, and saved labor costs associated with manual cleaning.

Frequently Asked Questions (FAQs)

1. What types of surfaces can the CE Water Jet Cleaning Machine clean?

The CE Water Jet Cleaning Machine is versatile and can clean a variety of surfaces, including metal, concrete, and plastic.

2. Is it safe to use the machine indoors?

Yes, as long as proper ventilation is maintained and operators use appropriate PPE.

3. How often should I perform maintenance on the machine?

Regular maintenance should be performed at least once every 6 months, or more frequently based on usage.

4. Can the machine be used for removing graffiti?

Absolutely, the high-pressure water jets can effectively remove graffiti from various surfaces without damaging the underlying material.

5. Are there any specific training requirements for operators?

Operators should undergo training to understand the machine’s operation, safety protocols, and maintenance requirements.

Conclusion

The **CE Water Jet Cleaning Machine** has established itself as an indispensable tool in the realm of industrial cleaning. Its efficiency, cost-effectiveness, and versatility across various applications make it a preferred choice for companies looking to enhance their cleaning processes. By adopting this technology, industries not only improve cleanliness but also contribute to environmental sustainability, ultimately leading to a safer and healthier work environment. Embrace the future of industrial cleaning with the CE Water Jet Cleaning Machine and experience the difference it can make.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design