Why Choose High Pressure Water Jet Pumps for Your Industrial Applications?

Understanding the Basics of High Pressure Water Jet Pumps

High pressure water jet pumps are specialized equipment designed to deliver water at extremely high pressures, often exceeding 20,000 psi. These pumps harness the power of water to perform various tasks, including cleaning, cutting, and surface preparation. Their versatility and effectiveness make them essential in numerous industrial applications.

The Mechanism Behind High Pressure Water Jet Pumps

To appreciate the benefits of high pressure water jet pumps, it's crucial to understand how they operate. Typically, these pumps utilize a high-pressure system that forces water through a narrow nozzle. The result is a concentrated stream of water that can cut through hard materials or effectively clean surfaces. The mechanics involve:

1. High-Pressure Generation

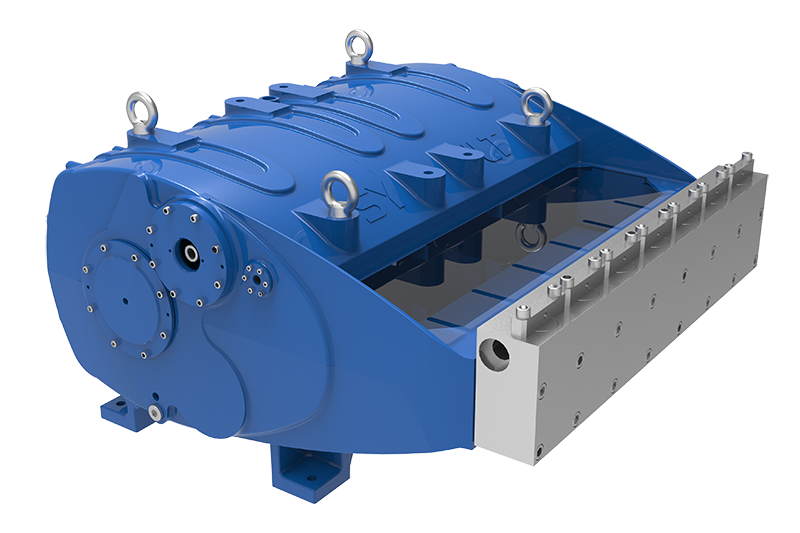

The heart of the high pressure water jet pump is its ability to generate pressure. This is achieved through various pump types, including plunger pumps and diaphragm pumps, which harness mechanical force to pressurize water.

2. Nozzle Design

The design of the nozzle plays a critical role in determining the effectiveness of the water jet. Different nozzle configurations can create varying spray patterns, which can be optimized for specific tasks like cutting or cleaning.

Types of Nozzles Available

- **Fan Nozzles:** Ideal for surface cleaning due to their wide spray pattern.

- **Rotary Nozzles:** Suitable for heavy-duty cleaning as they provide a concentrated rotating jet.

- **Cutting Nozzles:** Designed for precision cutting, allowing for intricate work on materials like metal and stone.

Key Advantages of High Pressure Water Jet Pumps

Choosing high pressure water jet pumps for industrial applications offers numerous benefits. Here are some of the most compelling reasons:

1. Environmentally Friendly Solution

High pressure water jetting is a green technology. By using water as the primary cleaning medium, it minimizes the need for harsh chemicals. This not only reduces chemical waste but also makes the process safer for workers and the environment.

2. Versatility in Applications

High pressure water jet pumps are incredibly versatile. They can be utilized for a wide range of applications, including:

Surface Preparation

Before painting or coating, surfaces often need to be cleaned and prepped. Water jet pumps can effectively remove contaminants like rust, dirt, and grease.

Concrete Cutting and Demolition

These pumps can cut through concrete and other tough materials with precision, making them ideal for demolition projects.

Pipe Cleaning

High pressure water jets can clear blockages in pipes without damaging the infrastructure, ensuring efficient flow and reducing downtime.

3. Cost-Effective Operations

Investing in high pressure water jet pumps can lead to significant cost savings over time. Their efficiency reduces labor costs, and their ability to complete tasks quickly means less downtime for your operations.

4. Enhanced Safety Features

Modern high pressure water jet pumps come equipped with safety features such as pressure relief valves and automatic shut-off systems. These features mitigate risks associated with high-pressure systems, ensuring a safer working environment.

5. Precision and Control

One of the standout features of high pressure water jet pumps is their precision. Operators can control the pressure and flow rate, allowing for tailored applications that meet specific needs.

Factors to Consider When Choosing High Pressure Water Jet Pumps

When selecting high pressure water jet pumps, several factors should be taken into account to ensure you choose the ideal equipment for your needs.

1. Pressure Requirements

Different applications require different pressure levels. It's essential to evaluate the maximum pressure needed for your specific tasks to choose an appropriate pump.

2. Flow Rate

The flow rate, measured in gallons per minute (GPM), determines how quickly a pump can complete a task. Higher flow rates are generally more efficient for larger cleaning jobs.

3. Power Source

Consider the power source for your high pressure water jet pump. Options include electric, diesel, and gasoline-powered models, each with its own advantages and applications.

4. Portability

Depending on your operational needs, the portability of the pump may be a crucial factor. Some pumps are designed for stationary use, while others are portable and can be easily transported from one job site to another.

Maintenance and Care for High Pressure Water Jet Pumps

To ensure optimal performance and longevity of high pressure water jet pumps, regular maintenance is essential. Here are some critical maintenance tips:

1. Regular Inspections

Conduct routine inspections to check for leaks, wear, and tear on hoses, nozzles, and fittings. Identifying issues early can prevent costly repairs.

2. Cleaning Filters

Keeping filters clean is vital for maintaining the efficiency of the pump. Dirty filters can impede water flow and increase pressure on the pump, leading to potential damage.

3. Seasonal Maintenance

If the pump is not used year-round, ensure it is properly winterized or stored according to manufacturer specifications to prevent damage from freezing.

4. Lubrication

Regularly lubricate moving parts to reduce friction and wear, ensuring the pump operates smoothly.

Applications of High Pressure Water Jet Pumps in Various Industries

High pressure water jet pumps are utilized across numerous industries, each leveraging their unique capabilities to enhance productivity and efficiency.

1. Construction and Demolition

In construction, high pressure water jet pumps are used for cutting concrete, removing debris, and preparing surfaces for new installations.

2. Oil and Gas Industry

These pumps play a crucial role in cleaning pipelines, tanks, and other equipment, ensuring compliance with safety standards.

3. Manufacturing

Manufacturers utilize high pressure water jet pumps for precision cutting and surface preparation, enhancing the quality of finished products.

4. Marine Applications

In the marine sector, these pumps are essential for cleaning hulls and removing barnacles, ensuring fuel efficiency and vessel safety.

5. Food and Beverage Industry

High pressure water jetting is an effective cleaning method for food processing equipment, ensuring compliance with hygiene standards.

Frequently Asked Questions (FAQs)

1. What types of materials can high pressure water jet pumps cut through?

High pressure water jet pumps can cut through materials such as metal, concrete, stone, and composite materials, making them highly versatile.

2. How do I determine the right pressure for my application?

The right pressure depends on the material and the task at hand. It's best to consult with manufacturers or industry guides for specific recommendations.

3. Are high pressure water jet pumps safe to use?

Yes, when operated correctly and with proper safety measures in place, high pressure water jet pumps are safe. Always follow manufacturer guidelines and use appropriate protective gear.

4. Do high pressure water jet pumps require a lot of maintenance?

While they do require regular maintenance, proper care can significantly extend the life of the pump and keep it operating efficiently.

5. Can high pressure water jet pumps be used for both cleaning and cutting?

Absolutely! High pressure water jet pumps are designed for both cleaning and cutting applications, making them highly versatile tools for various industries.

Conclusion

High pressure water jet pumps are invaluable tools in modern industrial applications. Their ability to deliver high-pressure water efficiently opens the door to a myriad of applications, from cleaning and cutting to surface preparation. By understanding the advantages, maintenance needs, and application possibilities, businesses can make informed decisions on incorporating high pressure water jet pumps into their operations. Investing in this technology not only enhances productivity but also contributes to a safer and more environmentally friendly working environment.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design