How to Choose the Right Classy High Pressure Low Flow Pump for Your Needs

Table of Contents

- Understanding High Pressure Low Flow Pumps

- Key Factors in Choosing a Pump

- Types of High Pressure Low Flow Pumps

- Efficiency and Energy Consumption

- Maintenance and Reliability

- Frequently Asked Questions

- Conclusion

Understanding High Pressure Low Flow Pumps

High pressure low flow pumps are specialized devices designed to move liquids at high pressures while maintaining a relatively low flow rate. These pumps are essential in various industrial applications, including chemical processing, oil and gas, and water treatment. Their ability to deliver fluids efficiently under high pressure makes them invaluable in maintaining system integrity and functionality.

Key Factors in Choosing a Pump

Selecting the right high pressure low flow pump requires a thorough understanding of several key factors that influence pump performance and suitability for specific applications.

Application Requirements

Before diving into technical specifications, it's crucial to identify your specific application needs. Consider the following:

- **Fluid Characteristics**: What type of fluid will you be pumping? Is it corrosive, viscous, or abrasive?

- **Temperature Variations**: Will the pump be operating in extreme temperatures?

- **Environmental Conditions**: Are there any external factors like dust or moisture that could affect the pump's performance?

Understanding these requirements will help narrow down your options.

Flow Rate and Pressure

Two critical parameters when selecting a pump are flow rate and pressure.

- **Flow Rate**: This is the volume of fluid the pump can deliver in a specific time frame, measured in gallons per minute (GPM) or liters per minute (LPM). For low flow applications, this rate is typically below 20 GPM.

- **Pressure**: This refers to the force with which the pump delivers fluid, measured in pounds per square inch (PSI) or bar. Higher pressure ratings are essential for applications that require overcoming significant resistance.

Carefully assess your system's requirements to ensure the pump can deliver the necessary flow and pressure.

Pump Materials and Design

The materials used in constructing a high pressure low flow pump significantly impact its durability and performance. Common materials include stainless steel, cast iron, and plastics, each offering different benefits:

- **Stainless Steel**: Highly resistant to corrosion and ideal for harsh chemicals.

- **Cast Iron**: Durable and cost-effective for non-corrosive fluids.

- **Plastic**: Lightweight and resistant to corrosion for specific applications.

Additionally, consider the pump design, as different configurations will influence efficiency and suitability for your application.

Types of High Pressure Low Flow Pumps

Different types of high pressure low flow pumps cater to various needs. Understanding these types will help you select the most suitable option.

Gear Pumps

Gear pumps are positive displacement pumps that utilize interlocking gears to move fluids. They are particularly effective for low-viscosity fluids and offer consistent flow rates. Applications include fuel delivery and hydraulic systems.

Diaphragm Pumps

Diaphragm pumps use a flexible diaphragm to create a vacuum that draws fluid into the pump. They excel in applications requiring the handling of corrosive or abrasive fluids, making them popular in the chemical industry.

Piston Pumps

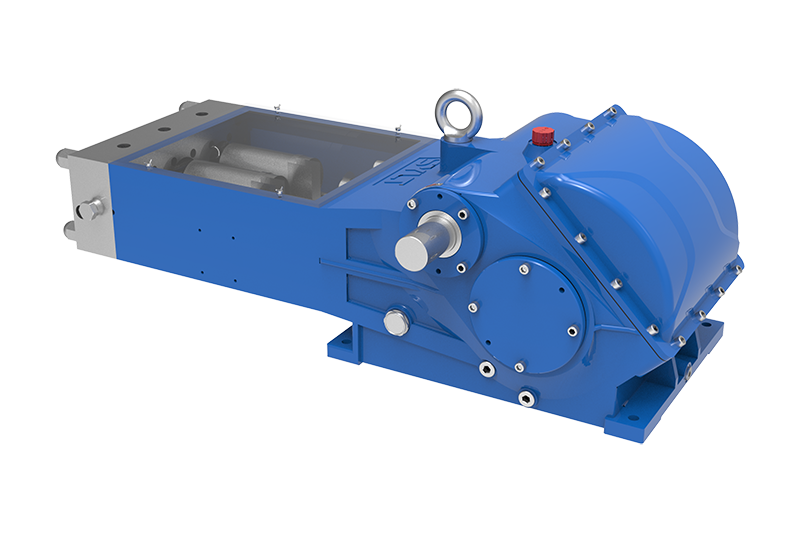

Piston pumps utilize a reciprocating piston to generate high pressure. They are capable of handling a wide range of fluids, including those with high viscosity. These pumps are often used in hydraulic applications and water jet cutting.

Efficiency and Energy Consumption

Efficiency is a critical consideration when selecting a pump. An efficient pump will reduce operational costs and extend the lifespan of the pump. Look for pumps with high volumetric efficiency and low energy consumption ratings. Additionally, consider:

- **Variable Speed Drives**: These allow for adjustments in flow and pressure, optimizing performance and energy usage.

- **System Design**: Ensure your entire pumping system is designed for efficiency, as it can impact the pump’s overall performance.

Maintenance and Reliability

Choosing a pump that requires minimal maintenance can save time and money in the long run. Look for features that enhance reliability, such as:

- **Self-priming capabilities**: This reduces the risk of cavitation and damage.

- **Sealing mechanisms**: Proper seals prevent leaks and protect internal components.

Regular maintenance practices can also enhance the lifespan of pumps, including routine inspections and fluid checks.

Frequently Asked Questions

1. What is the difference between high pressure low flow pumps and standard pumps?

High pressure low flow pumps are specifically designed to operate at high pressures while maintaining low flow rates, making them suitable for specialized applications. Standard pumps may not offer the same pressure capabilities or flow control.

2. How do I determine the right flow rate for my system?

The right flow rate can be determined by analyzing your system's requirements, including the fluid type, application needs, and pressure drops throughout the system.

3. Can high pressure low flow pumps handle corrosive fluids?

Yes, many high pressure low flow pumps are designed with materials resistant to corrosion, such as stainless steel and specific plastics, making them suitable for handling corrosive fluids.

4. How often should I perform maintenance on my pump?

Maintenance frequency can vary based on the pump type and application. However, routine inspections and fluid checks should be conducted regularly to ensure optimal performance.

5. Are there energy-efficient options for high pressure low flow pumps?

Yes, many high pressure low flow pumps are designed with energy efficiency in mind, featuring variable speed drives and low energy consumption ratings.

Conclusion

Choosing the right classy high pressure low flow pump requires careful consideration of various factors, including application requirements, flow rate, pressure, materials, and maintenance needs. By understanding the different types of pumps available and their respective advantages, you can make a well-informed decision that meets your operational demands. Investing in the right pump not only ensures system efficiency but also enhances reliability and reduces operational costs. With this comprehensive guide, you are now equipped to navigate the complexities of selecting the ideal high pressure low flow pump for your unique needs.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design