The Essential Guide to Choosing the Right Fancy High Pressure Booster Pump for Your Needs

Table of Contents

- 1. Introduction to High Pressure Booster Pumps

- 2. Understanding Pump Functionality and Applications

- 3. Key Features to Consider When Choosing a Booster Pump

- 4. Types of High Pressure Booster Pumps

- 5. Installation and Setup of Your Booster Pump

- 6. Maintenance and Care for Longevity

- 7. Common Issues and Solutions

- 8. Conclusion

- 9. FAQs about High Pressure Booster Pumps

1. Introduction to High Pressure Booster Pumps

High pressure booster pumps are essential components in various industries, serving the critical function of increasing water pressure for different applications. Whether you’re dealing with irrigation, domestic water supply, or industrial processes, understanding how to select the right pump is crucial for efficiency and performance. In this guide, we delve deeply into the world of fancy high pressure booster pumps, helping you navigate through the selection process seamlessly.

2. Understanding Pump Functionality and Applications

Booster pumps operate by enhancing the pressure of fluid systems. They are most commonly used in scenarios where the existing water pressure is insufficient, such as:

2.1 Residential Applications

In homes, booster pumps are often utilized to ensure adequate water pressure throughout the property, particularly in multi-story buildings where gravity can impede flow.

2.2 Industrial Applications

In industrial settings, these pumps are vital for processes that require high pressure, including cooling systems and various manufacturing operations.

2.3 Agricultural Uses

Farmers rely on high-pressure booster pumps for effective irrigation and crop management, ensuring that water reaches its destination efficiently.

3. Key Features to Consider When Choosing a Booster Pump

Selecting the right high pressure booster pump requires careful consideration of several key features:

3.1 Flow Rate

The flow rate, measured in gallons per minute (GPM), is a critical factor as it determines how much water the pump can move within a specific timeframe.

3.2 Pressure Rating

The pressure rating, expressed in pounds per square inch (PSI), indicates the maximum pressure the pump can deliver, which is vital for applications with high pressure requirements.

3.3 Motor Type

The type of motor, whether it’s electric or gas-powered, affects the efficiency, ease of use, and maintenance of the pump. Electric motors are more common for residential applications, while gas motors might be preferred for mobile or heavy-duty industrial applications.

3.4 Build Quality

The construction materials of the pump play a significant role in durability. Stainless steel and cast iron are common choices that ensure longevity and resistance to corrosion.

3.5 Noise Level

For residential applications, the noise produced by a booster pump is a vital consideration. Low-noise models are preferable for maintaining a peaceful home environment.

4. Types of High Pressure Booster Pumps

Understanding the different types of booster pumps can clarify which model best suits your needs.

4.1 Centrifugal Pumps

These pumps use a rotating impeller to increase the pressure of liquids. They are ideal for applications requiring a steady flow rate.

4.2 Positive Displacement Pumps

These pumps work by trapping a fixed amount of liquid and forcing it into the discharge pipe, making them suitable for applications needing high pressure and low flow rates.

4.3 Inline Booster Pumps

Inline booster pumps are designed for easy installation into existing pipework, providing a space-saving solution for pressure boosting.

4.4 Multistage Pumps

Featuring multiple impellers, multistage pumps are capable of achieving high pressure levels effectively, making them ideal for industrial applications.

5. Installation and Setup of Your Booster Pump

Proper installation is crucial for the optimal functioning of your booster pump. Here are some steps to guide you through the process:

5.1 Selecting the Location

Choose a location close to the water source and power supply while keeping accessibility for maintenance in mind.

5.2 Installing the Pump

Follow the manufacturer’s guidelines for installation. Ensure that all connections are secure and leak-free.

5.3 Connecting to Power Supply

If the pump is electric, ensure it’s connected to a suitable power supply, adhering to electrical safety standards.

5.4 Testing the System

Once installed, test the pump to ensure it operates correctly and efficiently.

6. Maintenance and Care for Longevity

Regular maintenance is essential to extend the lifespan of your high pressure booster pump:

6.1 Routine Inspections

Conduct periodic checks for leaks, unusual noises, or vibrations, which can indicate underlying issues.

6.2 Cleaning the Filter

If your pump has a filter, clean it regularly to prevent blockages that can hinder performance.

6.3 Lubrication

Ensure all moving parts are properly lubricated as per the manufacturer’s recommendations.

7. Common Issues and Solutions

Understanding common problems can help in maintaining your booster pump effectively.

7.1 Low Water Pressure

If the pressure is lower than expected, check for blockages in the intake line or ensure that the pump is correctly sized for your application.

7.2 Unusual Noises

Noises can indicate mechanical wear or misalignment. Address these issues immediately to prevent further damage.

7.3 Overheating

If the pump overheats, ensure it’s receiving adequate water supply, as running dry can cause severe damage.

8. Conclusion

Choosing the right fancy high pressure booster pump is paramount for achieving optimal performance in various applications. By understanding the functionality, key features, and types of pumps available, as well as adhering to proper installation and maintenance practices, you can ensure longevity and efficiency. It's important to invest time in researching and selecting a pump that meets your specific needs, thereby avoiding potential issues and enhancing overall satisfaction.

9. FAQs about High Pressure Booster Pumps

9.1 What is a high pressure booster pump?

A high pressure booster pump increases the water pressure in a system, making it ideal for various applications requiring enhanced flow rates.

9.2 How do I determine the right size booster pump for my needs?

Calculate your required flow rate and pressure to select a pump that meets these specifications. Consulting with a professional can also be beneficial.

9.3 Can I install a booster pump myself?

Yes, but it requires basic plumbing and electrical knowledge. Following manufacturer guidelines is crucial for safe installation.

9.4 What maintenance does a booster pump require?

Regular inspections, cleaning filters, and lubricating moving parts are essential maintenance practices.

9.5 How long can I expect my booster pump to last?

With proper maintenance, a high-quality booster pump can last anywhere from 5 to 15 years, depending on usage and environment.

By following this comprehensive guide, you can confidently choose the right high pressure booster pump that meets your specific needs, ensuring optimal performance and reliability in your applications.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

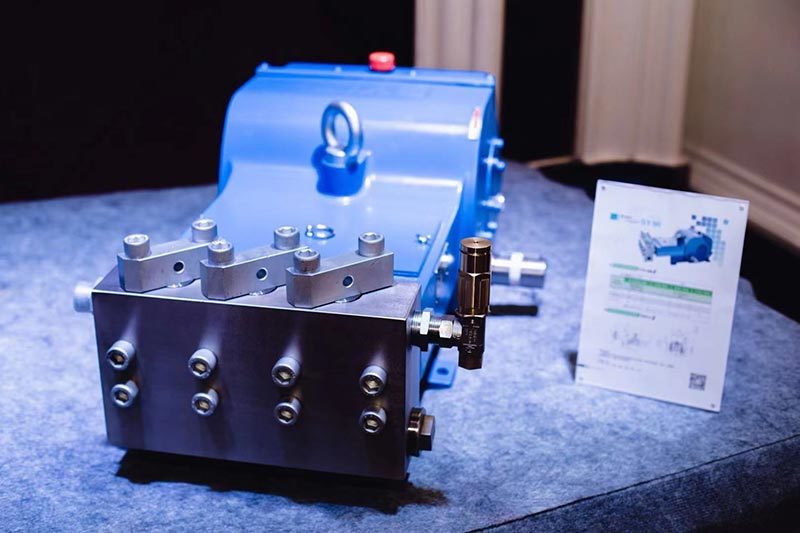

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design