Application of High-Pressure Plunger Pumps in the Ship Cleaning Industry

Application of High-Pressure Plunger Pumps in the Ship Cleaning Industry

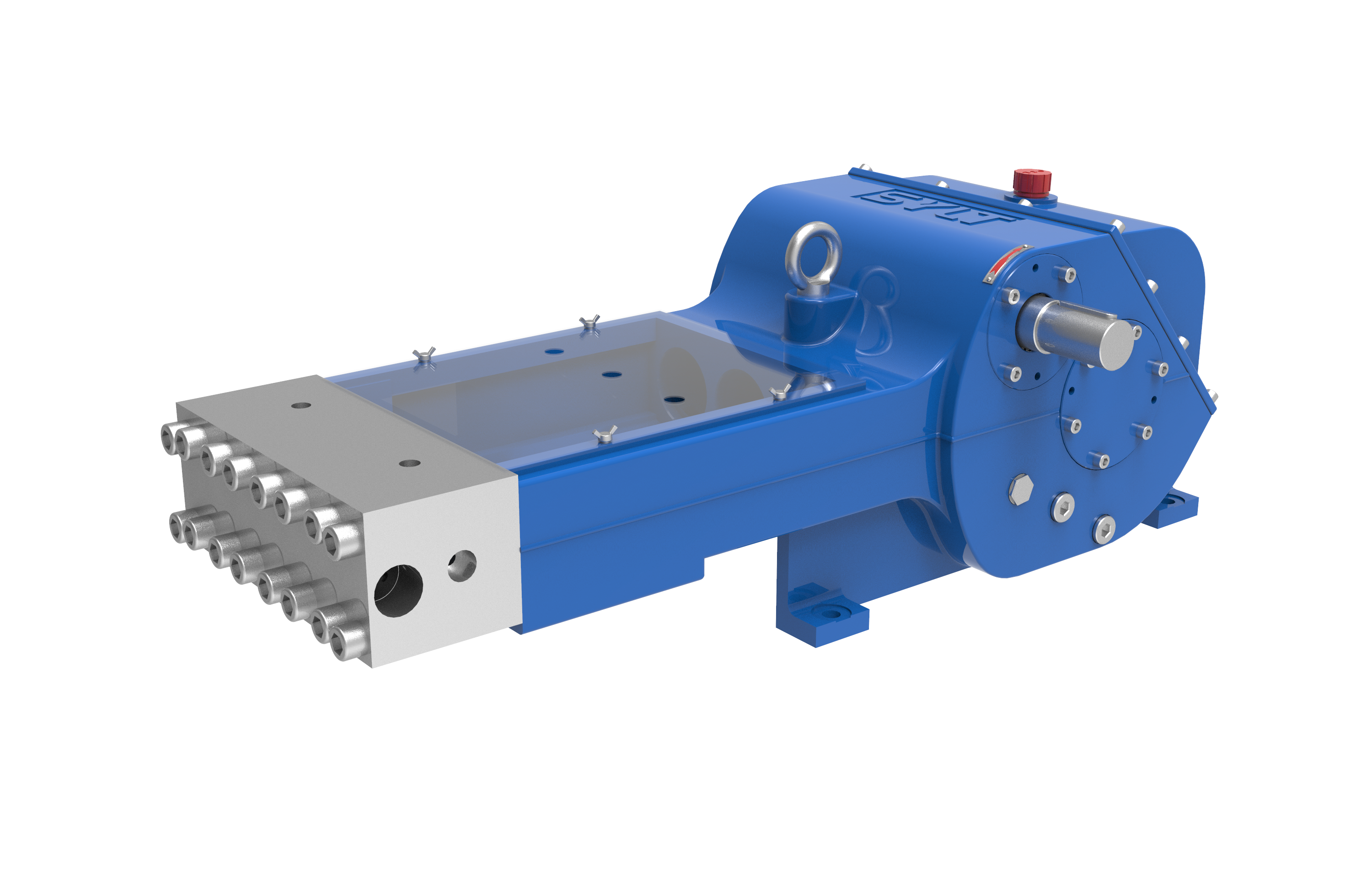

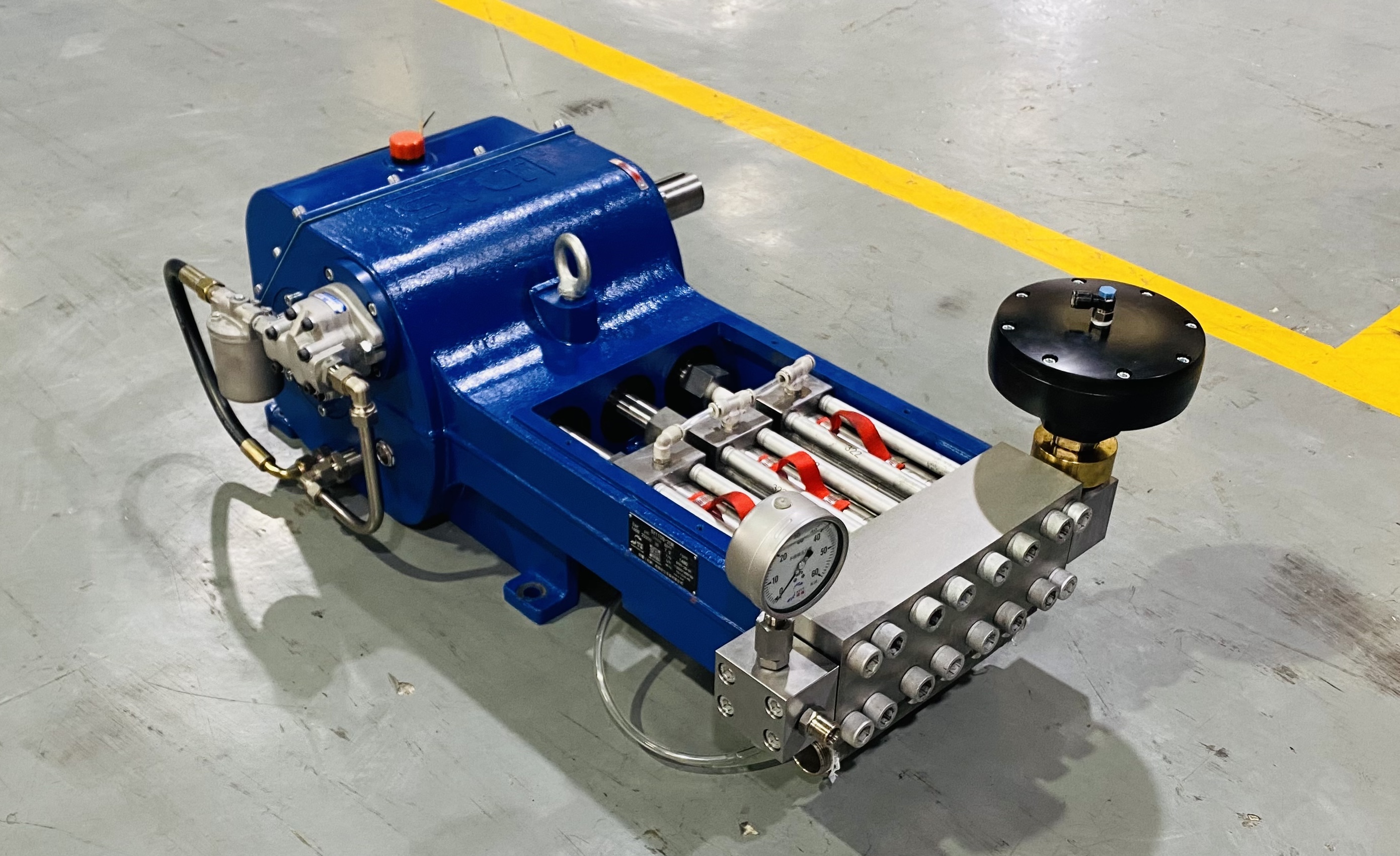

Abstract: When ships operate in a marine environment for a long time, the hull surface is prone to the attachment of marine organisms, rust, and dirt, affecting ship performance and fuel efficiency. High-pressure plunger pumps, with their high pressure, large flow rate, and durability, have become key equipment in the ship cleaning industry.

I. Challenges of Ship Cleaning

Ship cleaning faces the following challenges:

Stubborn attachments: Marine organisms, rust, and dirt adhere tightly and are difficult to remove.

Large cleaning area: The hull surface area is huge, requiring efficient cleaning equipment.

High environmental requirements: The cleaning process must consider environmental protection to avoid polluting the ocean.

II. Advantages of High-Pressure Plunger Pumps

High-pressure plunger pumps have the following advantages in ship cleaning:

High pressure: Generates pressure above 800 bar, effectively removing stubborn attachments such as marine organisms and rust.

Large flow rate: High flow ensures the efficiency of large area cleaning, avoiding prolonged construction time.

Strong durability: Made of wear-resistant materials, especially key components in the hydraulic end, suitable for long-term high-intensity operation.

Environmentally friendly: Uses clean water to reduce environmental pollution.

III. Applications of High-Pressure Plunger Pumps in Ship Cleaning

High-pressure plunger pumps are mainly used in the following cleaning scenarios:

Hull cleaning: Removes marine organisms, rust, and dirt, restoring the smoothness of the hull surface.

Deck cleaning: Removes oil stains and salt residues, keeping the deck clean.

Cargo hold cleaning: Cleans the cargo hold to prevent cargo contamination and corrosion.

IV. Key Points for Selecting High-Pressure Plunger Pumps

When selecting high-pressure plunger pumps, the following factors should be considered:

Pressure: Choose the appropriate pressure based on cleaning needs, without blindly pursuing excessively high pressure.

Flow rate: Select flow rate based on cleaning area and efficiency requirements.

Power: Determine power based on pressure and flow rate.

Material: Choose wear-resistant and corrosion-resistant materials, especially for the water-passing parts.

V. Development Trends

In the future, high-pressure plunger pumps will develop in the following directions:

High pressure and flow: Improve cleaning efficiency.

Intelligent: Achieve automatic control and remote monitoring.

Environmentally friendly: Reduce air, water source, and noise pollution.

Conclusion: High-pressure plunger pumps, with their efficiency, durability, and environmentally friendly characteristics, have become indispensable equipment in the ship cleaning industry. With technological advancements, high-pressure plunger pumps will play a greater role in ship cleaning, contributing to the green development of the shipping industry.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design