Why Choose Advanced High Pressure Plunger Pumps for Your Industrial Needs?

Introduction to Advanced High Pressure Plunger Pumps

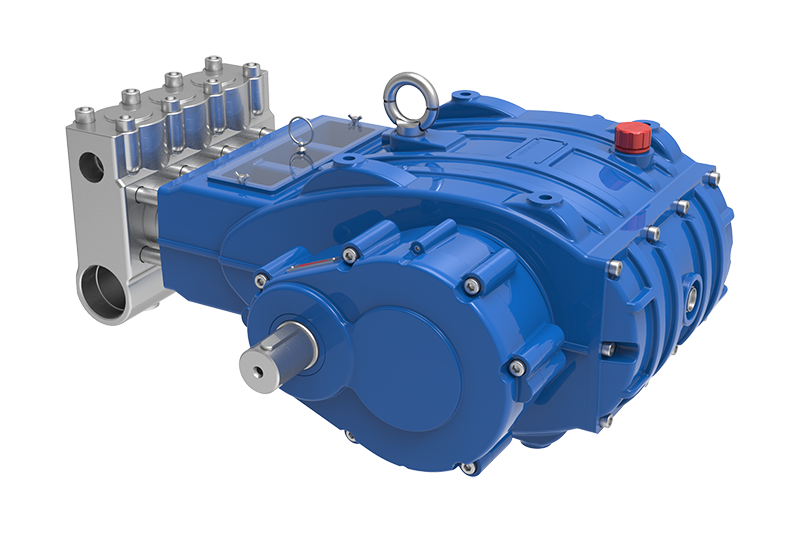

In the realm of industrial machinery, **high-pressure plunger pumps** stand out as essential components across various sectors, from oil and gas to pharmaceuticals and food processing. These pumps are engineered to deliver precise fluid handling capabilities, ensuring efficiency and reliability in even the most demanding environments. In this article, we will delve into the unique advantages of choosing advanced high-pressure plunger pumps for your industrial applications, highlighting their functionality, efficiency, and versatility.

Understanding the Functionality of Plunger Pumps

What Are Plunger Pumps?

**Plunger pumps** operate using a reciprocating mechanism where a plunger moves back and forth within a cylinder, creating pressure that forces liquid through the pump. This design allows for the transport of various fluids, including corrosive and viscous materials, making them ideal for multiple industrial applications.

Key Features of High Pressure Plunger Pumps

1. **High Efficiency**: Plunger pumps are known for their efficiency in handling high-viscosity fluids.

2. **Variable Flow Rates**: These pumps can be adjusted for varying flow rates, accommodating different operational needs.

3. **Robust Design**: Built from durable materials, plunger pumps can withstand harsh industrial environments.

The Advantages of Advanced High Pressure Plunger Pumps

1. Enhanced Efficiency

Advanced high-pressure plunger pumps are engineered to maximize efficiency, reducing energy consumption while maintaining high performance. The precision of the plunger mechanism minimizes fluid loss, ensuring that every stroke delivers optimal output. This level of efficiency is particularly beneficial in industries where fluid handling can account for significant operational costs.

2. Cost-Effectiveness

While the initial investment in high-pressure plunger pumps may be higher than other pump types, their **long-term cost-effectiveness** is undeniable. Reduced energy consumption and lower maintenance costs lead to significant savings over time. Moreover, the reliability of these pumps decreases the likelihood of unexpected downtimes, further enhancing financial performance.

3. Versatility in Industrial Applications

Plunger pumps are incredibly versatile. They can handle a wide range of fluids, including:

- **Corrosive liquids**: Suitable for chemical processing industries.

- **Viscous fluids**: Ideal for food and beverage applications.

- **Slurries**: Effective in mining and mineral processing.

This adaptability allows businesses to utilize a single pump type across multiple applications, streamlining inventory and reducing operating costs.

4. Precision and Control

The ability to control flow rates and pressure makes advanced high-pressure plunger pumps particularly valuable in applications requiring **precision dosing**. Industries such as pharmaceuticals and chemicals benefit from the exactitude these pumps offer, ensuring compliance with safety and regulatory standards.

Common Applications of High Pressure Plunger Pumps

1. Oil and Gas Industry

In the oil and gas sector, high-pressure plunger pumps are employed for various tasks, including enhanced oil recovery and **well stimulation**. Their ability to handle high-pressure environments while maintaining flow integrity is crucial for operational success.

2. Food and Beverage Processing

The food and beverage industry relies on plunger pumps for sanitary fluid handling. They ensure that fluids such as sauces, syrups, and other viscous products are transported without contamination, adhering to industry regulations.

3. Chemical Processing

Chemical manufacturing often involves moving hazardous or corrosive fluids. High-pressure plunger pumps are built to withstand these challenging conditions while providing reliable performance over extended periods.

Maintenance and Longevity of Plunger Pumps

Extending the Life of Your Pump

Regular maintenance is vital in extending the lifespan of high-pressure plunger pumps. Here are some tips to ensure your pumps continue to operate efficiently:

- **Routine inspections**: Regularly check seals and fittings for wear and tear.

- **Fluid quality**: Ensure the fluids being pumped meet the specifications required for optimal performance.

- **Cleaning**: Periodic cleaning of pump components prevents buildup that can lead to inefficiency.

Signs Your Plunger Pump Needs Attention

Being proactive is essential. Signs that your high-pressure plunger pump may need maintenance include:

- Unusual noises or vibrations

- Fluctuating flow rates

- Leaks or external wear

Choosing the Right High Pressure Plunger Pump for Your Needs

Factors to Consider

When selecting a high-pressure plunger pump, consider the following:

- **Application requirements**: Understand the viscosity and nature of the fluids.

- **Pressure ratings**: Ensure the pump can handle the required pressure for your application.

- **Flow rate**: Assess the necessary flow rate for operational efficiency.

Top Brands and Models

There are numerous reputable brands that offer advanced high-pressure plunger pumps. Researching and comparing models can help you find the perfect fit for your industrial needs. Key players in the market include:

- **Parker Hannifin**

- **Kamat**

- **Cat Pumps**

Frequently Asked Questions (FAQs)

1. What are the main benefits of using high-pressure plunger pumps?

The benefits include enhanced efficiency, cost-effectiveness, versatility across applications, and precision control for fluid handling.

2. How do I maintain a high-pressure plunger pump?

Routine inspections, fluid quality checks, and periodic cleaning are essential for maintaining your pump.

3. Can plunger pumps handle corrosive fluids?

Yes, high-pressure plunger pumps are specifically designed to handle corrosive and hazardous fluids, making them ideal for chemical processing.

4. What industries commonly use high-pressure plunger pumps?

Common industries include oil and gas, food and beverage processing, and chemical manufacturing.

5. How do I choose the right high-pressure plunger pump for my application?

Consider factors such as application requirements, pressure ratings, and desired flow rates when selecting a pump.

Conclusion

Choosing advanced high-pressure plunger pumps for your industrial needs is a strategic decision that can lead to improved efficiency, reduced costs, and enhanced versatility across various applications. By understanding the unique features, maintenance requirements, and operational benefits of these pumps, you can make an informed choice that will contribute to the long-term success of your operations. As industries continue to evolve, investing in high-quality pump technology will ensure that your business remains competitive and capable of meeting the demands of the future.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design