How Quality Plunger High Pressure Pumps Revolutionize Industrial Processes

Table of Contents

- Introduction to Plunger High Pressure Pumps

- Understanding Plunger Pumps: Mechanics and Functionality

- Benefits of High-Quality Plunger High Pressure Pumps in Industrial Settings

- Applications of Plunger High Pressure Pumps Across Industries

- Key Features of Quality Plunger Pumps

- Choosing the Right Plunger High Pressure Pump for Your Needs

- Maintenance Tips for Prolonging the Life of Plunger Pumps

- The Future of Plunger High Pressure Pumps in Industry

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Plunger High Pressure Pumps

In today's fast-paced industrial landscape, efficiency and reliability are paramount. **Plunger high pressure pumps** have emerged as vital components that significantly enhance industrial processes. These pumps are engineered for high performance, making them indispensable in various applications, from chemical processing to water treatment. Understanding their mechanics and applications is crucial for businesses aiming to optimize their operations.

Understanding Plunger Pumps: Mechanics and Functionality

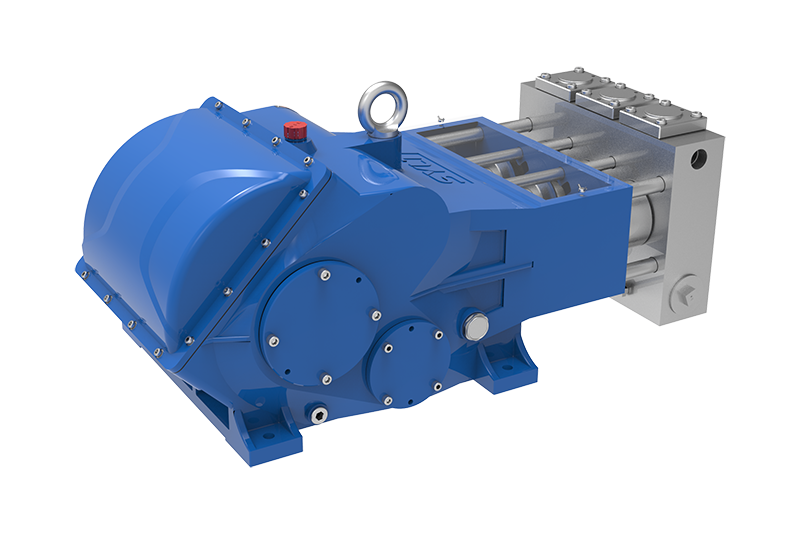

Plunger pumps operate on the principle of positive displacement, utilizing a reciprocating plunger to move fluids at high pressure. The design typically consists of a cylinder, a plunger, and inlet and outlet valves. When the plunger moves within the cylinder, it creates a vacuum that draws fluid in through the inlet valve. As the plunger moves back, the fluid is expelled through the outlet valve.

Mechanics Behind Plunger Pumps

The mechanics of plunger pumps allow them to handle various fluid types, including viscous, abrasive, and corrosive substances. The following are key aspects of their functionality:

- High Efficiency: Plunger pumps are known for their ability to maintain consistent pressure and flow rates, ensuring optimal performance.

- Versatility: They can be used in multiple industries, adapting to different fluid properties and operational requirements.

- Durability: Constructed from robust materials, these pumps withstand harsh conditions, extending their operational lifespan.

Benefits of High-Quality Plunger High Pressure Pumps in Industrial Settings

Investing in high-quality plunger pumps can provide numerous advantages for industrial operations:

Increased Efficiency

Quality plunger pumps are designed to operate efficiently, reducing downtime and energy consumption. Their ability to maintain high pressure while minimizing energy loss translates into significant cost savings.

Enhanced Reliability

Reliability is crucial in industrial settings. High-quality plunger pumps are engineered to function consistently under various operating conditions, thereby minimizing the risk of failures that can halt production.

Improved Safety

Safety is paramount in industrial processes. Plunger pumps are designed with safety features that prevent leaks and over-pressurization, protecting both workers and the environment.

Versatile Applications

From **chemical manufacturing** to **mining operations**, plunger pumps can be utilized in a wide array of applications. Their adaptability makes them a valuable asset in any industrial setting.

Applications of Plunger High Pressure Pumps Across Industries

Plunger high pressure pumps are employed in various sectors, showcasing their versatility and effectiveness. Here are some key applications:

Chemical Processing

In the chemical industry, plunger pumps facilitate the transfer of hazardous materials and aggressive chemicals. Their robust construction ensures safe handling and accurate dosing.

Water Treatment

Plunger pumps play a crucial role in water treatment facilities, where they are used for dosing chemicals and managing high-pressure water flows. Their reliability ensures the consistent quality of treated water.

Oil and Gas

In the oil and gas sector, plunger pumps are essential for transporting crude oil and other fluids at high pressures. They are designed to withstand the challenging conditions of extraction and refining processes.

Food and Beverage Industry

The food and beverage industry relies on plunger pumps for precise dosing and transfer of ingredients. Their ability to handle viscous fluids while maintaining hygiene standards is critical in this sector.

Key Features of Quality Plunger Pumps

When selecting a plunger pump, understanding its features is essential for optimizing performance. Here are critical characteristics to consider:

Material Composition

High-quality plunger pumps are made from materials resistant to corrosion and wear, ensuring longevity, especially in harsh environments.

Pressure Ratings

The pressure rating indicates the pump’s capacity for handling specific applications. Choosing a pump with the appropriate pressure rating is crucial for maintaining operational efficiency.

Flow Rate

The flow rate of a plunger pump determines how much fluid can be moved in a given time. Selecting a pump with the right flow rate is vital for meeting production demands.

Maintenance Requirements

Quality plunger pumps are designed for easy maintenance, allowing for quick inspections and repairs. This feature minimizes downtime and enhances overall productivity.

Choosing the Right Plunger High Pressure Pump for Your Needs

Selecting the appropriate plunger pump involves several considerations:

Assessing Your Application Needs

Understanding the specific requirements of your application, including fluid type, viscosity, and desired flow rate, is crucial for choosing the right pump.

Evaluating Performance Specifications

Review the performance specifications of potential pumps, focusing on pressure ratings, flow rates, and efficiency to ensure they align with your operational goals.

Considering Manufacturer Reputation

Opt for pumps from reputable manufacturers known for quality and reliability. Research reviews and testimonials to gauge the performance of different brands.

Budget Constraints

While quality is paramount, it's essential to consider your budget. Balance performance features with cost to find a pump that meets your needs without overspending.

Maintenance Tips for Prolonging the Life of Plunger Pumps

Proper maintenance is key to ensuring the longevity and reliability of plunger pumps. Here are some essential tips:

Regular Inspections

Conduct routine inspections to check for signs of wear, leaks, or abnormal vibrations. Early detection of issues can prevent more significant problems down the line.

Fluid Quality Management

Ensure that the fluids being pumped are of the appropriate quality. Contaminated or unsuitable fluids can damage the pump components over time.

Follow Manufacturer Guidelines

Adhere to the manufacturer's maintenance recommendations, including lubrication schedules and replacement intervals for wear parts.

Training Personnel

Provide training for personnel operating the pumps to ensure they understand proper usage and maintenance procedures. This can significantly reduce the risk of operator-induced issues.

The Future of Plunger High Pressure Pumps in Industry

The future of plunger high pressure pumps is promising, with advancements in technology leading to even greater efficiency and reliability. Emerging trends to watch include:

Integration of Smart Technology

Smart technology is becoming increasingly prevalent in industrial equipment. Future plunger pumps may incorporate IoT capabilities for real-time monitoring and predictive maintenance.

Focus on Sustainability

As industries shift toward sustainable practices, plunger pumps will likely evolve to reduce energy consumption and minimize environmental impact.

Enhancements in Material Science

Advancements in materials science will lead to stronger, more durable components that can withstand extreme conditions, further enhancing the lifespan and performance of pumps.

Frequently Asked Questions (FAQs)

1. What industries commonly use plunger high pressure pumps?

Plunger high pressure pumps are widely used in industries such as chemical processing, water treatment, oil and gas, and food and beverage manufacturing.

2. How do I know which plunger pump is right for my application?

Assess your application needs, including fluid type, viscosity, and required flow rate. Consult with manufacturers for recommendations based on your specific requirements.

3. What maintenance practices are essential for plunger high pressure pumps?

Regular inspections, ensuring fluid quality, adhering to manufacturer guidelines, and providing operator training are crucial maintenance practices.

4. Can plunger pumps handle corrosive fluids?

Yes, quality plunger pumps are designed with materials that can withstand corrosive fluids. However, it's essential to choose pumps specifically rated for such applications.

5. What is the typical lifespan of a plunger high pressure pump?

The lifespan of a plunger pump varies based on usage and maintenance but can range from 5 to 20 years with proper care.

Conclusion

Quality plunger high pressure pumps play a transformative role in enhancing industrial processes. Their ability to deliver high efficiency, reliability, and versatility makes them a crucial asset across various sectors. By understanding their mechanics, applications, and maintenance requirements, businesses can leverage the full potential of these pumps, driving productivity and efficiency in their operations. As we look to the future, innovations in technology and materials will only further revolutionize the role of plunger pumps in the industrial landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design