How Newest Industrial High Pressure Pumps Enhance Efficiency in Manufacturing

Table of Contents

- Introduction to Industrial High Pressure Pumps

- Understanding High Pressure Pumps

- The Importance of Efficiency in Manufacturing

- Recent Advancements in High Pressure Pump Technology

- Benefits of New High Pressure Pumps in Manufacturing

- Case Studies: Real-World Applications of High Pressure Pumps

- Future Trends in High Pressure Pump Technology

- FAQs About High Pressure Pumps

- Conclusion: Embracing Efficiency with New High Pressure Pumps

Introduction to Industrial High Pressure Pumps

In the modern manufacturing landscape, efficiency is paramount. Industrial high-pressure pumps play a crucial role in various applications, including chemical processing, oil and gas, and water treatment. The latest advancements in high-pressure pump technology are not just about pushing fluids; they are about transforming how industries operate. By enhancing efficiency, these pumps are becoming indispensable tools for manufacturers seeking to reduce operational costs and increase productivity.

Understanding High Pressure Pumps

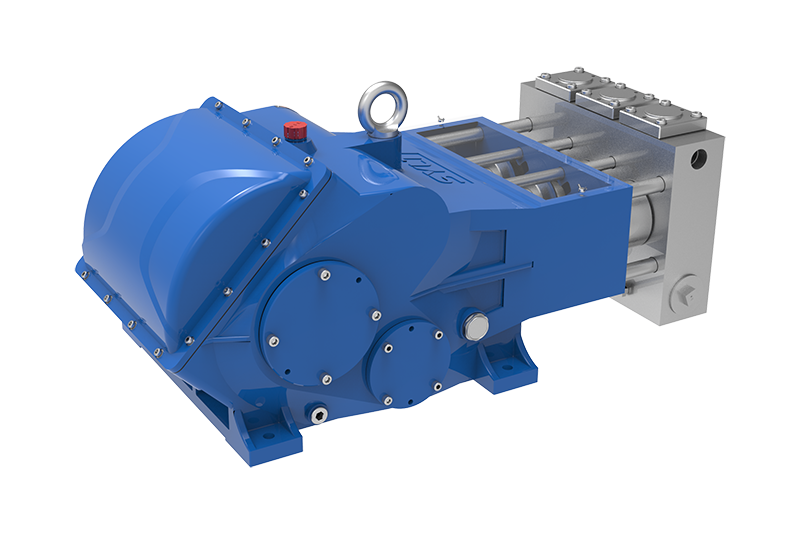

High-pressure pumps are designed to move fluids at elevated pressures, allowing for the efficient transportation of liquids and gases in various industrial processes. They operate on the principle of converting mechanical energy into hydraulic energy, which is then used to generate high-pressure fluid flow.

Types of High Pressure Pumps

Several types of high-pressure pumps are commonly used in manufacturing, including:

- **Centrifugal Pumps**: Ideal for high flow rates and low viscosity fluids.

- **Positive Displacement Pumps**: Best for high viscosity fluids and applications requiring precise flow control.

- **Diaphragm Pumps**: Used in applications where chemical compatibility is crucial, providing leak-free operation.

Each type has its unique advantages and is selected based on specific application requirements.

The Importance of Efficiency in Manufacturing

Efficiency in manufacturing directly correlates with profitability. As businesses face rising operational costs, the need to optimize every aspect of production becomes critical. High-pressure pumps significantly contribute to this optimization by:

- **Reducing Energy Consumption**: Modern pumps are engineered to operate efficiently, consuming less energy for the same output.

- **Minimizing Downtime**: Advanced technology ensures reliability, reducing the frequency of maintenance and breakdowns.

- **Improving Process Speed**: Enhanced flow rates facilitate quicker production cycles, enabling manufacturers to meet demand without compromising quality.

Recent Advancements in High Pressure Pump Technology

The landscape of high-pressure pumps is evolving rapidly, with innovations leading to improved performance, efficiency, and reliability. Key advancements include:

Smart Pump Technology

The integration of IoT (Internet of Things) technology allows for real-time monitoring and analytics. Smart pumps can predict maintenance needs, optimize performance, and reduce energy consumption.

Energy-Efficient Designs

Manufacturers are focusing on designing pumps that minimize energy wastage. This includes the use of advanced materials and streamlined geometries to reduce friction and improve flow dynamics.

Enhanced Materials

The use of advanced materials, such as composites and stainless steel, improves durability and resistance to corrosion, which is essential for maintaining efficiency over time.

Benefits of New High Pressure Pumps in Manufacturing

The latest high-pressure pumps offer a host of benefits that can significantly enhance manufacturing processes:

Improved Performance

New designs and technologies result in higher pressures and flow rates, allowing manufacturers to process fluids more quickly and efficiently.

Cost Savings

By reducing energy consumption and maintenance costs, businesses can significantly lower their operational expenses, leading to higher profit margins.

Environmental Impact

Enhanced efficiency often leads to reduced waste and emissions, contributing to a more sustainable manufacturing process.

Case Studies: Real-World Applications of High Pressure Pumps

Examining real-world applications can illustrate the transformative power of modern high-pressure pumps.

Case Study 1: Chemical Processing Facility

A leading chemical processing plant integrated high-efficiency pumps into their operations. The result was a 30% reduction in energy costs alongside a 25% increase in production output.

Case Study 2: Water Treatment Plant

In a municipal water treatment facility, the adoption of advanced high-pressure pumps led to improved filtration processes, which decreased chemical usage by 15%, thus enhancing environmental sustainability.

Future Trends in High Pressure Pump Technology

As industries continue to evolve, high-pressure pumps will follow suit. Emerging trends include:

Increased Automation

Future pumps will likely integrate more automation, allowing for independent operation and enhanced control over manufacturing processes.

Green Technology Focus

With an increasing emphasis on sustainability, future high-pressure pumps will be designed with materials and technologies that minimize their environmental impact.

FAQs About High Pressure Pumps

1. What applications are high pressure pumps commonly used for?

High pressure pumps are used in various industries, including chemical processing, oil and gas extraction, water treatment, and food processing.

2. How do I choose the right high-pressure pump for my application?

Choosing the right pump depends on factors such as fluid type, required flow rate, pressure specifications, and compatibility with existing systems.

3. What maintenance is required for high-pressure pumps?

Regular maintenance includes checking seals, bearings, and filters, as well as ensuring proper lubrication and addressing any wear and tear.

4. Can high-pressure pumps handle corrosive fluids?

Yes, many high-pressure pumps are designed with materials that resist corrosion, making them suitable for handling aggressive chemicals.

5. What is the lifespan of a typical high-pressure pump?

The lifespan of a high-pressure pump can vary widely, but with proper maintenance, many can last 10-15 years or longer.

Conclusion: Embracing Efficiency with New High Pressure Pumps

The newest industrial high-pressure pumps are revolutionizing the way manufacturing processes operate. By enhancing efficiency, reducing costs, and minimizing environmental impact, these pumps are not just tools but essential components of modern manufacturing. As industries continue to adopt these advancements, the potential for increased productivity and sustainability will only grow. Embracing the latest high-pressure pump technology is not merely an option; it is a necessity for manufacturers aiming to thrive in a competitive landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design