Finding the Best Deals on High Pressure Pumps for Industrial Use

Table of Contents

- Understanding High Pressure Pumps: What You Need to Know

- Exploring Different Types of High Pressure Pumps

- Key Specifications to Consider When Buying High Pressure Pumps

- Where to Find the Best Deals on High Pressure Pumps

- Negotiating the Best Prices for High Pressure Pumps

- Maintenance Tips for High Pressure Pumps

- Common Mistakes to Avoid When Purchasing High Pressure Pumps

- FAQs about High Pressure Pumps

- Conclusion

Understanding High Pressure Pumps: What You Need to Know

High pressure pumps are specialized devices designed to handle the movement of fluids at elevated pressures. They are crucial in various industrial applications, including oil and gas, chemical processing, and wastewater treatment. These pumps can handle corrosive materials and operate effectively in demanding environments. Understanding the fundamental concepts behind high pressure pumps will aid in making informed purchasing decisions.

Why High Pressure Pumps are Essential in Industry

In industrial settings, high pressure pumps serve multiple purposes. They are often used for:

- **Transferring fluids over long distances**

- **Feeding boilers and other machinery requiring high-pressure inputs**

- **Facilitating chemical reactions** by maintaining optimal pressure levels

- **Cleaning and maintenance** in processes where high-pressure water jets are needed

A solid grasp of their functionality will allow you to select the best pump for your specific requirements.

Exploring Different Types of High Pressure Pumps

There are various types of high pressure pumps, each tailored to specific applications and fluids. Understanding these distinctions can help in determining the right pump for your needs.

Centrifugal Pumps

Centrifugal pumps are designed to move fluids by converting rotational energy into kinetic energy. They are commonly used for water and wastewater applications.

Piston Pumps

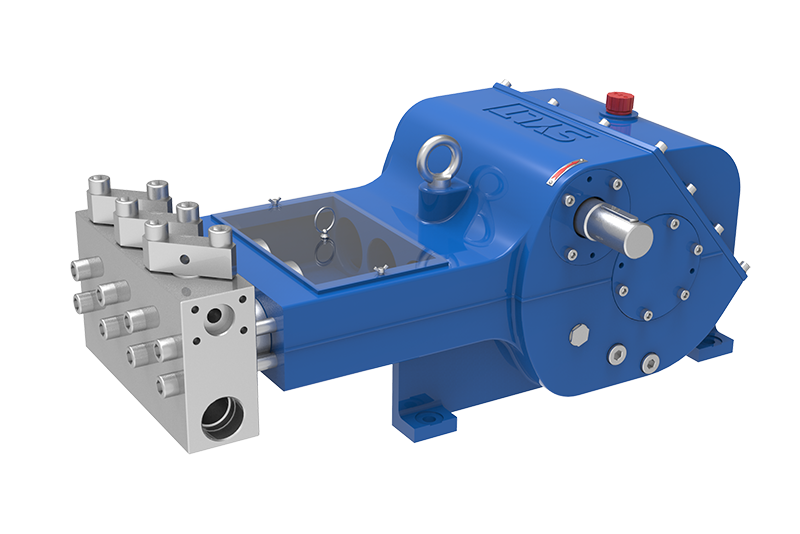

Piston pumps utilize a reciprocating mechanism to move fluid. These pumps are prevalent in applications requiring high pressure and low flow rates, such as hydraulic systems.

Diaphragm Pumps

Diaphragm pumps are ideal for handling corrosive or viscous fluids. They operate by moving a diaphragm back and forth, creating a vacuum that draws in and expels fluids.

Positive Displacement Pumps

These pumps are specifically engineered to move a fixed volume of fluid with each rotation or stroke. They are particularly effective in high-viscosity applications.

Key Specifications to Consider When Buying High Pressure Pumps

Selecting the right high pressure pump involves understanding specific technical specifications. Here are some crucial factors to consider:

Flow Rate

The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid the pump can move. Ensure the selected pump can meet your operational demands.

Pressure Rating

Each pump has a maximum pressure limit. Verify that the pump’s pressure rating aligns with your application requirements to prevent potential equipment failure.

Materials of Construction

High pressure pumps must withstand various environmental conditions. Look for pumps constructed from durable materials such as stainless steel or heavy-duty plastic, especially if the fluids are corrosive.

Power Source

Consider whether the pump will be powered by electricity, diesel, or other fuel types. This choice will impact operational costs and efficiency.

Where to Find the Best Deals on High Pressure Pumps

Finding competitive prices on high pressure pumps requires strategic sourcing. Here are some recommendations:

Online Marketplaces

Platforms such as Amazon, eBay, and specialized industrial equipment websites often list high pressure pumps at competitive prices. Regularly checking these sites allows you to take advantage of discounts and special offers.

Manufacturer Websites

Purchasing directly from manufacturers can lead to significant savings. Many manufacturers offer promotions or bulk purchase discounts that are not available through third-party vendors.

Local Distributors

Building relationships with local distributors can yield beneficial deals and insights into upcoming sales or promotions. Local distributors often have a better understanding of regional needs and can make tailored recommendations.

Trade Shows and Expos

Attending industrial trade shows is an excellent opportunity to find special pricing on high pressure pumps. Interacting directly with manufacturers and distributors can lead to exclusive offers not found elsewhere.

Negotiating the Best Prices for High Pressure Pumps

Negotiation is a vital component of securing the best deal when purchasing high pressure pumps. Here are some effective strategies:

Know Your Market

Conduct thorough market research to understand standard pricing for the pump type you require. This knowledge will bolster your negotiating position and help avoid overpaying.

Leverage Competition

Don’t hesitate to inform sellers that you are considering multiple vendors. This tactic can encourage them to offer better pricing or terms to close the deal.

Ask for Discounts

Simply asking for discounts or promotional pricing can yield good results. Many manufacturers and distributors are willing to negotiate, particularly for bulk orders.

Maintenance Tips for High Pressure Pumps

To ensure longevity and optimal performance of high pressure pumps, regular maintenance is essential. Here are some best practices:

Routine Inspections

Conduct regular inspections to check for signs of wear and tear, leaks, or unusual noises. Early identification of issues can prevent costly repairs later.

Regular Cleaning

Keep the pump and its components clean to prevent clogs and inefficiencies. Use appropriate cleaning agents that are compatible with the materials of the pump.

Lubrication

Ensure that all moving parts are adequately lubricated according to the manufacturer’s guidelines to avoid friction-related damage.

Monitor Performance

Track the pump’s performance metrics regularly to identify any deviations from its normal operating conditions. This monitoring allows for proactive issue resolution.

Common Mistakes to Avoid When Purchasing High Pressure Pumps

Making informed decisions is crucial when investing in high pressure pumps. Avoid these common pitfalls:

Ignoring Specifications

Always pay attention to the pump’s specifications. Overlooking critical details can lead to selecting a pump that does not meet your requirements.

Buying Based on Price Alone

While budget considerations are important, selecting a pump solely based on price can lead to poor performance. Focus on value rather than just the cost.

Neglecting After-Sales Support

Consider the level of after-sales support offered by the manufacturer or distributor. Quality support can be invaluable in addressing any issues post-purchase.

FAQs about High Pressure Pumps

1. What is the typical lifespan of a high pressure pump?

The lifespan of a high pressure pump can vary significantly based on usage and maintenance, but generally, they can last anywhere from 5 to 20 years.

2. How do I determine the right pressure rating for my application?

Evaluate the maximum pressure requirements of your system and select a pump with a rating that comfortably exceeds this value to ensure safe and efficient operation.

3. Are high pressure pumps energy-efficient?

Yes, many modern high pressure pumps are designed to be energy-efficient, reducing operational costs while maintaining performance standards.

4. Can high pressure pumps handle corrosive fluids?

Certain high pressure pumps are specifically designed with materials that can resist corrosion, making them suitable for handling aggressive fluids. Always check the material compatibility.

5. What maintenance is required for high pressure pumps?

Regular maintenance includes inspections, cleaning, lubrication, and performance monitoring to ensure the pump operates efficiently and to extend its lifespan.

Conclusion

Finding the best deals on high pressure pumps for industrial use requires a blend of knowledge, research, and strategic buying. By understanding the types of pumps, key specifications, and effective purchasing strategies, we can secure valuable investments that enhance operational efficiency. Regular maintenance and avoiding common pitfalls will ensure these pumps provide consistent performance for years to come. Equip yourself with the right information and make informed decisions for your industrial needs.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design