Why Choosing the Best High Pressure Pump is Essential for Your Business

Table of Contents

- Introduction to High Pressure Pumps

- Understanding High Pressure Pumps

- The Importance of Selecting the Right High Pressure Pump

- Applications of High Pressure Pumps in Various Industries

- Factors to Consider When Choosing a High Pressure Pump

- Top High Pressure Pump Manufacturers

- Maintenance and Service: Ensuring Longevity of Your Pump

- Conclusion

- FAQs About High Pressure Pumps

Introduction to High Pressure Pumps

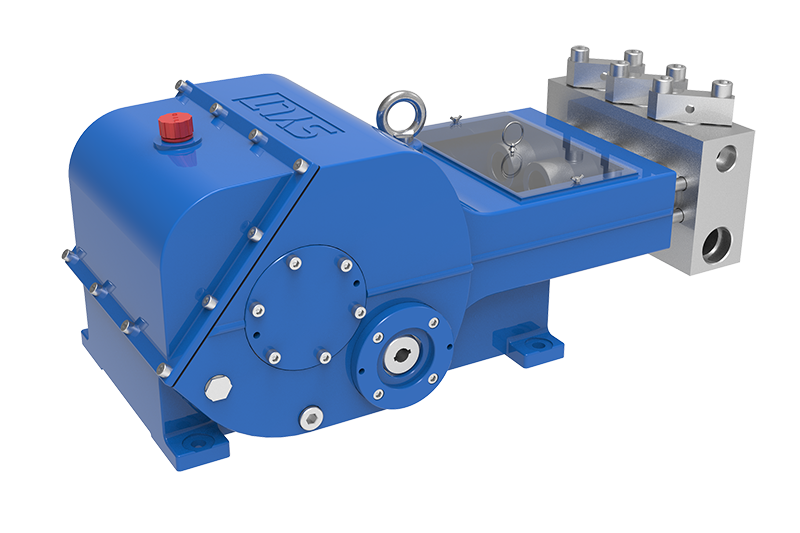

In today's fast-paced industrial landscape, **high-pressure pumps** play a crucial role in ensuring efficient operations across various sectors. These pumps are designed to move fluids at significantly high pressures, making them indispensable for processes that require the transfer of liquids and gases. From manufacturing to construction, understanding the importance of choosing the right high-pressure pump can directly impact your business's operational efficiency and bottom line.

Understanding High Pressure Pumps

High-pressure pumps are specialized devices that overcome resistance to fluid flow, allowing for the movement of substances through pipelines and other systems. Unlike standard pumps, high-pressure pumps can generate pressures that exceed 1000 psi, catering to demanding applications. There are various types of high-pressure pumps, including:

Types of High Pressure Pumps

- **Positive Displacement Pumps**: These pumps trap a fixed amount of fluid and then discharge it at high pressure. They are suitable for viscous fluids and offer precise flow control.

- **Centrifugal Pumps**: Utilizing rotational energy, these pumps are ideal for low-viscosity fluids and can achieve high flow rates.

- **Diaphragm Pumps**: Known for their ability to handle corrosive and abrasive fluids, diaphragm pumps use a flexible diaphragm to create pressure.

The Importance of Selecting the Right High Pressure Pump

Choosing the right high-pressure pump is not merely a matter of preference; it is essential for several reasons:

1. Operational Efficiency

Selecting a pump that aligns with your specific application ensures optimal performance. An appropriate pump minimizes energy consumption and maximizes fluid transfer efficiency, significantly improving operational workflows.

2. Cost Reduction

Investing in the right high-pressure pump can lead to significant cost savings. By reducing energy expenses, maintenance costs, and the risk of breakdowns, the right choice becomes a crucial component of your business strategy.

3. Enhanced Productivity

The right pump ensures a consistent and reliable supply of fluids, enhancing overall productivity. This reliability is essential for industries where downtime can lead to substantial losses.

4. Safety Considerations

High-pressure systems pose inherent risks. Choosing a reliable pump with safety features reduces the risk of leaks, spills, and accidents, protecting both personnel and the environment.

Applications of High Pressure Pumps in Various Industries

High-pressure pumps find applications across diverse industries, including:

1. Manufacturing

In manufacturing, high-pressure pumps are used for processes like **metal cleaning, surface treatment, and hydraulic systems**, making them indispensable for efficient production lines.

2. Construction

The construction industry relies on high-pressure pumps for concrete spraying, water jet cutting, and efficient water management during excavation and drilling.

3. Oil and Gas

In the oil and gas sector, these pumps are critical for enhanced oil recovery processes and transporting crude oil and natural gas under high pressure.

4. Food and Beverage

High-pressure pumps play a significant role in food processing, including applications such as pasteurization and sterilization, ensuring product safety and quality.

Factors to Consider When Choosing a High Pressure Pump

When selecting a high-pressure pump, consider the following factors:

1. Application Requirements

Understand the specific needs of your application, including the type of fluid, pressure requirements, and flow rates. This will guide your selection process.

2. Material Compatibility

Different materials are suitable for various fluids. Ensure the pump material can withstand the chemical properties of the fluid to prevent premature wear and failure.

3. Power Source

Choose between electric, diesel, or hydraulic power sources based on your operational environment and efficiency requirements.

4. Maintenance Needs

Consider the maintenance requirements of the pump. Some high-pressure pumps are designed for easier servicing, which can save time and costs in the long run.

5. Manufacturer Reputation

Research reliable manufacturers known for quality products and excellent customer support. Their reputation can provide insights into the pump's performance and reliability.

Top High Pressure Pump Manufacturers

Several manufacturers are renowned for their high-quality high-pressure pumps. Some of the leading brands include:

1. Grundfos

A global leader in advanced pump solutions, Grundfos offers a diverse range of high-pressure pumps known for their reliability and energy efficiency.

2. KSB

With a long-standing reputation, KSB provides innovative pump solutions catering to various industrial applications, ensuring durability and performance.

3. Cat Pumps

Specializing in high-pressure, positive displacement pumps, Cat Pumps is recognized for its high-quality products that meet the rigorous demands of numerous industries.

4. Wilo

Wilo is known for its innovative solutions and energy-efficient pumps, making it a preferred choice for many businesses seeking high-performance pumping systems.

Maintenance and Service: Ensuring Longevity of Your Pump

The longevity of a high-pressure pump relies heavily on regular maintenance and service. Implementing a robust maintenance schedule can prevent unexpected breakdowns and prolong the pump's life.

1. Regular Inspections

Conduct periodic inspections to identify any signs of wear, leaks, or other issues. Early detection can prevent more significant problems down the line.

2. Proper Lubrication

Ensure that all moving parts are adequately lubricated to reduce friction and wear, contributing to smoother operation and longer lifespan.

3. Component Replacement

Stay proactive in replacing worn-out parts, such as seals and bearings, before they lead to pump failure.

4. Training Personnel

Invest in training for your personnel to ensure they understand the operational intricacies and maintenance of high-pressure pumps, ensuring better performance and safety.

Conclusion

In conclusion, the significance of choosing the best high-pressure pump for your business cannot be overstated. It directly impacts operational efficiency, cost savings, and overall productivity. By understanding your application's requirements, considering essential factors, and selecting reputable manufacturers, you can ensure that your high-pressure pump will serve your business needs effectively. Investing time and resources in this critical decision will pay off in the long run, enabling your business to thrive in a competitive landscape.

FAQs About High Pressure Pumps

1. What is the typical lifespan of a high-pressure pump?

The lifespan of a high-pressure pump can vary significantly based on usage and maintenance. Generally, well-maintained pumps can last anywhere from 5 to 15 years.

2. How do I know which type of high-pressure pump is right for my application?

Evaluate your specific application requirements, including fluid type, flow rates, and pressure needs. Consulting with a pump specialist can also provide valuable insights.

3. Are high-pressure pumps energy-efficient?

Many modern high-pressure pumps are designed for energy efficiency. Selecting the right pump can lead to significant energy savings over time.

4. What maintenance is required for high-pressure pumps?

Regular inspections, lubrication, and timely replacement of worn components are key maintenance tasks to ensure the longevity and efficiency of high-pressure pumps.

5. Can high-pressure pumps handle corrosive fluids?

Certain types of high-pressure pumps are specifically designed to handle corrosive fluids. It is crucial to choose pumps made from compatible materials for these applications.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design