Unlocking Efficiency: The Advantages of High-Pressure Low-Flow Pumps for Industrial Applications

Table of Contents

1. Introduction to High-Pressure Low-Flow Pumps

2. Understanding the Mechanism of High-Pressure Low-Flow Pumps

3. Key Benefits of Using High-Pressure Low-Flow Pumps

3.1 Enhanced Energy Efficiency

3.2 Compact Design and Space Savings

3.3 Increased Reliability and Durability

3.4 Precise Control and Accuracy

3.5 Versatility in Applications

4. Applications of High-Pressure Low-Flow Pumps in Various Industries

4.1 Manufacturing Industry

4.2 Pharmaceutical Sector

4.3 Food and Beverage Processing

5. Choosing the Right High-Pressure Low-Flow Pump

6. Maintenance Tips for Long-Term Performance

7. Frequently Asked Questions

8. Conclusion

1. Introduction to High-Pressure Low-Flow Pumps

High-pressure low-flow pumps are increasingly becoming the backbone of various industrial processes. These specialized pumps are designed to deliver liquids at high pressures while maintaining a low flow rate, making them ideal for applications requiring precision and reliability. In this guide, we will explore the myriad benefits that high-pressure low-flow pumps offer to industries, helping businesses unlock efficiency and maximize their operational capabilities.

2. Understanding the Mechanism of High-Pressure Low-Flow Pumps

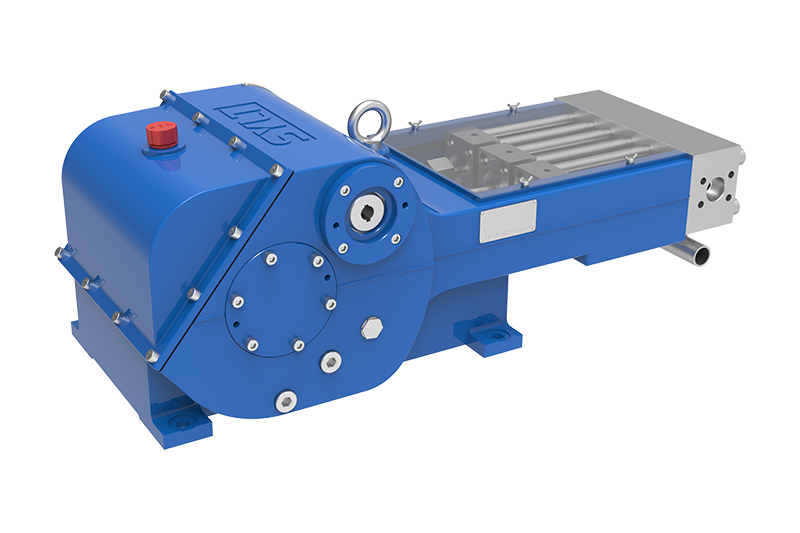

High-pressure low-flow pumps operate based on specific mechanical principles that allow them to generate significant pressure while controlling the flow rate. Typically, these pumps use mechanisms such as positive displacement or centrifugal action, depending on their design.

Positive displacement pumps move a fixed amount of fluid with each cycle, ensuring consistent flow and high pressure. In contrast, centrifugal pumps utilize a rotating impeller to increase the fluid's velocity, which in turn generates high pressure. Understanding these mechanisms is crucial for selecting the right pump for specific applications and ensuring optimal performance.

3. Key Benefits of Using High-Pressure Low-Flow Pumps

The advantages of using high-pressure low-flow pumps extend beyond just functionality. Here are some significant benefits:

3.1 Enhanced Energy Efficiency

High-pressure low-flow pumps are designed to consume less energy while providing superior performance. Their efficiency not only contributes to reduced operational costs but also aligns with sustainability goals. By minimizing energy consumption, companies can significantly lower their carbon footprint, making these pumps an environmentally responsible choice.

3.2 Compact Design and Space Savings

These pumps typically feature a compact design, allowing them to fit into tight spaces without compromising performance. This is particularly advantageous in facilities where space is at a premium, enabling businesses to maximize their floor space while still achieving high operational output.

3.3 Increased Reliability and Durability

Manufactured from high-quality materials, high-pressure low-flow pumps are built to withstand harsh industrial environments. Their durability ensures that they require less frequent replacements and repairs, reducing downtime and maintenance costs.

3.4 Precise Control and Accuracy

One of the standout features of high-pressure low-flow pumps is their ability to provide precise control over fluid delivery. This is essential in applications such as chemical processing, where accurate dosing is crucial to maintain product quality and safety.

3.5 Versatility in Applications

High-pressure low-flow pumps can serve a variety of industries and applications, making them a versatile choice for businesses. From fluid transfer in manufacturing to accurate dispensing in pharmaceuticals, these pumps can be tailored to meet specific operational needs.

4. Applications of High-Pressure Low-Flow Pumps in Various Industries

High-pressure low-flow pumps find applications across multiple sectors, each benefiting from their unique features.

4.1 Manufacturing Industry

In the manufacturing sector, these pumps are used for tasks such as material transport, chemical mixing, and pressure testing. Their reliability and efficiency make them indispensable for maintaining production lines and ensuring quality control.

4.2 Pharmaceutical Sector

The pharmaceutical industry relies on high-pressure low-flow pumps for precision dosing and sterile fluid transfer. These pumps help maintain stringent hygiene standards and ensure accurate formulations, vital for patient safety and regulatory compliance.

4.3 Food and Beverage Processing

In food and beverage processing, the accuracy of ingredient mixing and transfer is paramount. High-pressure low-flow pumps facilitate precise control over flow rates, ensuring the consistency and quality of the final product.

5. Choosing the Right High-Pressure Low-Flow Pump

When selecting a high-pressure low-flow pump, several factors must be considered to ensure optimal performance. Evaluate the following:

1. **Flow Rate Requirements**: Determine the specific flow rate needed for your application.

2. **Pressure Specifications**: Understand the pressure requirements necessary for effective operation.

3. **Fluid Characteristics**: Consider the type of fluid being pumped, including viscosity and chemical compatibility.

4. **Material Construction**: Ensure the pump is made from materials suitable for the operating environment and fluid type.

5. **Maintenance Needs**: Choose a pump that matches your maintenance capabilities and operational demands.

By carefully considering these factors, you can select a high-pressure low-flow pump that meets your specific requirements, enhancing your operational efficiency.

6. Maintenance Tips for Long-Term Performance

To ensure the longevity and efficiency of high-pressure low-flow pumps, regular maintenance is crucial. Here are some essential maintenance tips:

1. **Regular Inspections**: Schedule routine inspections to identify potential issues before they escalate.

2. **Clean Filters and Strainers**: Keep filters and strainers clean to prevent clogging and maintain optimal flow rates.

3. **Lubricate Moving Parts**: Regular lubrication of moving parts reduces wear and tear, extending the pump's lifespan.

4. **Monitor Performance**: Keep track of operational metrics, such as pressure and flow rates, to spot irregularities early.

5. **Follow Manufacturer Guidelines**: Adhere to the manufacturer's maintenance recommendations for best practices.

By implementing these maintenance practices, you can ensure that your high-pressure low-flow pumps operate at peak performance for years to come.

7. Frequently Asked Questions

What industries benefit most from high-pressure low-flow pumps?

High-pressure low-flow pumps are particularly beneficial in manufacturing, pharmaceuticals, and food and beverage processing, where precision and reliability are critical.

How do high-pressure low-flow pumps improve energy efficiency?

These pumps are designed to operate with lower energy consumption while providing the same or greater output, which reduces operational costs and carbon emissions.

What factors should I consider when selecting a high-pressure low-flow pump?

Key factors include flow rate and pressure requirements, fluid characteristics, material construction, and maintenance needs.

How often should I perform maintenance on my high-pressure low-flow pump?

Regular maintenance should be conducted based on the manufacturer's recommendations, with routine inspections and cleaning performed as needed.

Can high-pressure low-flow pumps handle corrosive fluids?

Yes, many high-pressure low-flow pumps are designed with materials that can handle corrosive fluids, but it’s essential to ensure compatibility with the specific fluid being pumped.

8. Conclusion

High-pressure low-flow pumps are a vital component in many industrial applications, providing numerous benefits that enhance efficiency, reliability, and sustainability. Their precise control, compact design, and versatility make them indispensable in sectors such as manufacturing, pharmaceuticals, and food processing. By understanding their mechanisms and advantages, businesses can make informed decisions that lead to improved operational performance and reduced costs.

Investing in high-pressure low-flow pumps not only boosts productivity but also aligns with modern demands for energy efficiency and environmentally responsible practices. As industries continue to evolve, these pumps will play an increasingly crucial role in unlocking efficiency and driving innovation.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design