Unleashing Power: How a Fancy High Pressure Booster Pump Transforms Industrial Processes

Table of Contents

- 1. Introduction to High Pressure Booster Pumps

- 2. Understanding High Pressure Booster Pumps

- 3. Applications in Industrial Processes

- 4. Benefits of Using High Pressure Booster Pumps

- 5. Selecting the Right Booster Pump for Your Needs

- 6. Maintenance Best Practices

- 7. Common Misconceptions About High Pressure Booster Pumps

- 8. Future Trends in High Pressure Booster Pump Technology

- 9. FAQs

- 10. Conclusion

1. Introduction to High Pressure Booster Pumps

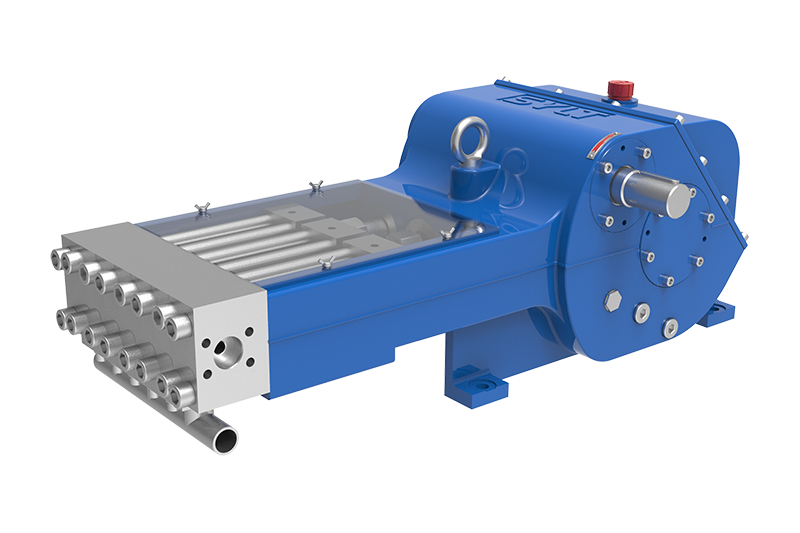

In today's fast-paced industrial environment, efficiency and performance are paramount. **High pressure booster pumps** have emerged as crucial components in optimizing industrial processes. These pumps increase fluid pressure to meet operational demands, ensuring that production systems run smoothly and effectively. This article delves into the intricacies of high pressure booster pumps, exploring their functionality, applications, benefits, and more.

2. Understanding High Pressure Booster Pumps

High pressure booster pumps are designed to elevate the pressure of liquids, making them essential in various industrial applications. These pumps work by utilizing mechanical energy to increase the pressure of incoming fluids. Typically, they are placed in-line with existing pumping systems and function to augment pressure as necessary.

**Types of High Pressure Booster Pumps**

- **Centrifugal Booster Pumps**: These pumps utilize rotational energy to increase fluid velocity, which in turn boosts pressure. They are widely used due to their efficiency and ability to handle large volumes.

- **Positive Displacement Booster Pumps**: Best suited for applications requiring high pressure at lower flow rates, these pumps trap a fixed amount of fluid and force it into the discharge pipe.

3. Applications in Industrial Processes

High pressure booster pumps find applications across a wide range of industries. Here are some key sectors where they play a vital role:

3.1 Water Supply Systems

In municipal water supply systems, these pumps ensure consistent water pressure, particularly in high-rise buildings and remote locations.

3.2 Oil and Gas Industry

The oil and gas sector relies heavily on booster pumps for transporting fluids over long distances, ensuring efficient flow through pipelines.

3.3 Food and Beverage Production

In food processing plants, high pressure booster pumps are critical for cleaning systems and processing applications, maintaining hygiene standards.

3.4 Chemical Processing

These pumps facilitate the transport of corrosive and viscous materials, making them indispensable in the chemical manufacturing industry.

3.5 HVAC Systems

In heating, ventilation, and air conditioning systems, high pressure booster pumps maintain optimal fluid pressure, improving system performance and energy efficiency.

4. Benefits of Using High Pressure Booster Pumps

Investing in high pressure booster pumps comes with numerous advantages that can significantly enhance operational efficiency.

4.1 Enhanced Efficiency

High pressure booster pumps are engineered for efficiency, allowing for reduced energy consumption while maintaining performance.

4.2 Improved System Performance

By ensuring that the necessary pressure levels are met, these pumps minimize downtime and keep processes running smoothly.

4.3 Cost Savings

Efficient operation translates to lower energy costs and reduced wear and tear on other equipment, leading to significant long-term savings.

4.4 Versatility

These pumps can be utilized in various applications, making them a versatile solution for multiple industries.

4.5 Safety Considerations

High pressure booster pumps equipped with safety features minimize operational hazards, promoting a safer working environment.

5. Selecting the Right Booster Pump for Your Needs

Choosing the right high pressure booster pump requires an understanding of specific operational needs and conditions. Here are key considerations:

5.1 Flow Rate Requirements

Calculate the required flow rate for your application to determine the appropriate pump size and type.

5.2 Pressure Specifications

Understand the pressure requirements of your system to ensure the pump can accommodate these needs.

5.3 Fluid Characteristics

Consider the type of fluid being pumped, including viscosity and temperature, to select a pump compatible with these conditions.

5.4 Energy Efficiency

Look for pumps that offer high efficiency ratings to reduce energy costs over time.

5.5 Maintenance Needs

Assess the maintenance requirements of different pump models to ensure minimal disruption to operations.

6. Maintenance Best Practices

Regular maintenance is essential to prolong the life of high pressure booster pumps and maintain their efficiency. Here are some best practices:

6.1 Routine Inspections

Conduct regular inspections to identify any signs of wear, leaks, or abnormal noises.

6.2 Lubrication

Ensure that pump components are properly lubricated to minimize friction and wear.

6.4 Monitor Performance

Keep track of performance metrics to detect any deviations from normal operation, allowing for timely interventions.

6.5 Professional Servicing

Engage professional services for complex maintenance tasks and troubleshooting to ensure optimal pump performance.

7. Common Misconceptions About High Pressure Booster Pumps

Despite their significance, several misconceptions surround high pressure booster pumps that can lead to suboptimal use.

7.1 "All Pumps Are the Same"

Different applications demand different pump types; selecting the right one is crucial for operational efficiency.

7.2 "Higher Pressure is Always Better"

While high pressure is essential, it must be balanced with flow rate and energy efficiency for optimal performance.

7.3 "Maintenance is Optional"

Neglecting maintenance can lead to costly repairs and reduced lifespan, making regular upkeep essential.

8. Future Trends in High Pressure Booster Pump Technology

The landscape of high pressure booster pumps continues to evolve with technological advancements. Here are some trends to watch:

8.1 Smart Pump Technology

Integrating IoT and AI into pump systems allows for real-time monitoring and adaptive performance adjustments.

8.2 Eco-Friendly Designs

The industry is moving towards more sustainable designs, focusing on energy efficiency and reduced environmental impact.

8.3 Advanced Materials

Utilizing innovative materials can enhance pump durability and performance, particularly in harsh environments.

9. FAQs

Q1: What factors affect the efficiency of high pressure booster pumps?

A1: Efficiency can be influenced by pump design, fluid characteristics, pressure levels, and maintenance practices.

Q2: How often should I maintain my high pressure booster pump?

A2: Routine inspections should be conducted monthly, with more thorough maintenance performed semi-annually or annually based on usage.

Q3: Can high pressure booster pumps handle corrosive fluids?

A3: Yes, many high pressure booster pumps are designed with materials that resist corrosion; however, the specific pump type should be chosen based on fluid characteristics.

Q4: What is the average lifespan of a high pressure booster pump?

A4: With proper maintenance, a high pressure booster pump can last anywhere from 10 to 20 years.

Q5: Are there energy-efficient options available for high pressure booster pumps?

A5: Yes, many manufacturers offer high efficiency models designed to minimize energy consumption while maintaining performance.

10. Conclusion

High pressure booster pumps serve as critical components in enhancing the efficiency and performance of industrial processes. With their ability to elevate fluid pressure, they find applications in diverse sectors such as water supply, oil and gas, food processing, and HVAC systems. Understanding their functionality, benefits, and maintenance needs empowers industries to make informed decisions that lead to enhanced productivity and significant cost savings. As technology continues to evolve, embracing advanced high pressure booster pumps will be key to maintaining a competitive edge in the industrial landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design