Unveiling the Secrets of High Pressure Pumps: Quality Plunger Insights

Table of Contents

1. Introduction to High Pressure Pumps

2. What are Plunger Pumps?

3. The Importance of Quality in High Pressure Plunger Pumps

4. How Plunger Pumps Work: An In-Depth Look

4.1 Components of a Plunger Pump

4.2 The Mechanism Behind High Pressure Generation

5. Applications of High Pressure Plunger Pumps

5.1 Industrial Cleaning Solutions

5.2 Oil and Gas Extraction

5.3 Chemical Processing

6. Factors Affecting Pump Performance and Longevity

6.1 Material Selection

6.2 Maintenance Protocols

7. Selecting the Right Plunger Pump for Your Needs

7.1 Key Specifications to Consider

7.2 Common Mistakes to Avoid

8. Frequently Asked Questions (FAQs)

9. Conclusion: Investing in Quality Plunger Pumps

1. Introduction to High Pressure Pumps

High-pressure pumps are pivotal in various industries, facilitating the movement of liquids at elevated pressures. These pumps are engineered to handle demanding applications, ensuring efficiency and reliability. Within this domain, plunger pumps stand out due to their unique design and operational advantages. This article provides a deep dive into high-pressure plunger pumps, unraveling their secrets and highlighting the importance of quality.

2. What are Plunger Pumps?

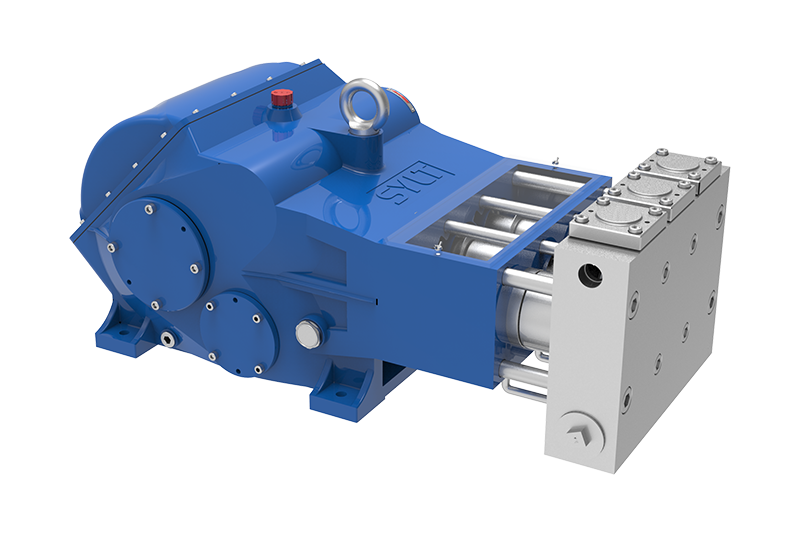

Plunger pumps, also known as positive displacement pumps, utilize a plunger mechanism to move fluids. The plunger's reciprocating motion creates a vacuum that draws liquid into the pump and then expels it under high pressure. This design enables them to deliver consistent flow rates, making them ideal for demanding applications.

3. The Importance of Quality in High Pressure Plunger Pumps

Quality is paramount when it comes to high-pressure pumps. A well-manufactured plunger pump ensures durability, reliability, and superior performance. Low-quality pumps may lead to frequent breakdowns and costly downtimes. Understanding the significance of quality in plunger pumps is crucial for industries aiming to maintain operational efficiency.

4. How Plunger Pumps Work: An In-Depth Look

Understanding the operation of plunger pumps involves examining their components and the mechanism behind high-pressure generation.

4.1 Components of a Plunger Pump

Key components of plunger pumps include:

- **Plunger**: The heart of the pump, responsible for creating pressure.

- **Cylinders**: Houses the plunger and serves as the fluid passageway.

- **Valves**: Control the flow of liquid into and out of the pump.

- **Drive Mechanism**: Powers the plunger's movement, which can be hydraulic or mechanical.

4.2 The Mechanism Behind High Pressure Generation

When the plunger moves downwards, it creates a vacuum in the cylinder, allowing liquid to enter. As the plunger moves upwards, the liquid is compressed and forced out through the discharge valve. This cyclical process generates high pressure and ensures a steady flow of liquid.

5. Applications of High Pressure Plunger Pumps

High-pressure plunger pumps find applications in various sectors, each benefitting from their unique capabilities.

5.1 Industrial Cleaning Solutions

In industrial settings, high-pressure plunger pumps are essential for cleaning machinery and equipment. Their ability to deliver powerful jets of water makes them effective for removing grime, oil, and other contaminants.

5.2 Oil and Gas Extraction

In the oil and gas industry, these pumps are used for enhanced oil recovery and fracturing processes. They provide the pressure necessary to inject fluids into oil wells, maximizing extraction rates.

5.3 Chemical Processing

Chemical manufacturing relies on precise fluid transfer, making plunger pumps indispensable. Their ability to handle corrosive and abrasive fluids further strengthens their position in this field.

6. Factors Affecting Pump Performance and Longevity

To maximize the performance and lifespan of high-pressure plunger pumps, several factors need consideration.

6.1 Material Selection

The materials used in manufacturing plunger pumps significantly influence their durability and effectiveness. Opting for high-quality materials resistant to wear and corrosion prolongs the pump's life.

6.2 Maintenance Protocols

Regular maintenance is crucial for ensuring optimal performance. Implementing a maintenance schedule that includes inspection, cleaning, and parts replacement can prevent unexpected failures and extend the lifespan of the pump.

7. Selecting the Right Plunger Pump for Your Needs

Choosing the appropriate plunger pump involves considering specific specifications and avoiding common pitfalls.

7.1 Key Specifications to Consider

When selecting a plunger pump, pay attention to:

- **Flow Rate**: Ensure it meets your operational requirements.

- **Maximum Pressure**: Choose a pump capable of handling your system’s pressure demands.

- **Material Compatibility**: Ensure the pump materials are suitable for the fluids being handled.

7.2 Common Mistakes to Avoid

Avoid these common mistakes when selecting a plunger pump:

- Overlooking the importance of quality.

- Failing to consider the specific application requirements.

- Not consulting with experts or manufacturers.

8. Frequently Asked Questions (FAQs)

What is the lifespan of a high-pressure plunger pump?

The lifespan varies based on usage, maintenance, and quality but can range from several years to decades with proper care.

How often should a plunger pump be serviced?

A typical service schedule is every 6 to 12 months, depending on usage and manufacturer recommendations.

Can plunger pumps handle abrasive fluids?

Yes, plunger pumps can handle abrasive fluids, but selecting a model made from wear-resistant materials is essential for longevity.

What are the signs of a failing plunger pump?

Common signs include unusual noises, fluctuations in pressure, and leaks around the pump.

Are high-pressure plunger pumps energy-efficient?

Yes, when properly sized and maintained, high-pressure plunger pumps can be quite energy-efficient compared to other pump types.

9. Conclusion: Investing in Quality Plunger Pumps

Understanding the intricacies of high-pressure plunger pumps is vital for industries that depend on reliable fluid movement. From their operational mechanics to their applications and maintenance needs, quality is the cornerstone of performance. Investing in high-quality plunger pumps not only enhances efficiency but also ensures longevity and reduces operational costs. By following the insights shared in this guide, businesses can make informed decisions that propel their operations forward.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design